Understanding Different Fiber Optic Splice Closures

Fiber optic splice closures are essential components in today's communication networks. These closures protect and organize splicingfiber connections, ensuring the integrity of opticalsignal transmission. The increasing demand for high-speed internet and bandwidth-intensive applications fuels the need for robust splicebox solutions. Fiberopticspliceclosure varieties include jointbox designs tailored to specific installation environments. A cablesplicer depends on these closures to maintain network efficiency. Fusionfiber technology enhances connectivity, supporting next-generation broadband technologies such as 5G and IoT. Choosing the right closure type ensures optimal performance and longevity across diverse applications.

Types of Fiber Optic Splice Closures

Horizontal Design

Design and Structure

Horizontal fiber optic splice closures offer a versatile solution for various network configurations. The design resembles a flat box, which allows easy installation in confined spaces. The structure of the horizontal closure provides ample space for organizing splicingfiber connections. The robust construction ensures protection against environmental factors. The 96Core Fiber Optic Splice Closure exemplifies this design by offering protection for spliced optical fiber points and cables. The horizontal design accommodates multiple cables and splices, making it suitable for complex networks.

Typical Applications

Horizontal splice closures find applications in both aerial and underground installations. Network providers often use these closures in urban settings where space constraints exist. The design supports high-density splicebox setups, which makes it ideal for metropolitan areas. The horizontal closure also suits environments requiring frequent maintenance, as the design allows easy access for a cablesplicer. The versatility of the horizontal design meets the demands of diverse network topologies.

Vertical Design

Design and Structure

Vertical fiber optic splice closures feature a domed shape, which provides a compact solution for buried applications. The design ensures that splicingfiber connections remain secure in harsh environments. The vertical structure offers a streamlined profile, which reduces the risk of damage from external forces. The design supports efficient opticalsignal transmission by minimizing potential disruptions. The vertical closure accommodates various cable types, enhancing its adaptability.

Typical Applications

Vertical splice closures excel in buried applications, where protection from environmental elements is critical. The design suits rural areas with extensive underground networks. The vertical closure also finds use in above-ground installations, where space optimization is necessary. The domed shape facilitates water drainage, which enhances durability in outdoor settings. Network operators prefer vertical closures for long-distance opticalsignal transmission, as the design supports stable performance.

Hybrid Fiber Enclosures

Design and Structure

Hybrid fiber enclosures combine splicingfiber capabilities with a patch panel, offering a comprehensive solution for network management. The design integrates both splicebox and patching functions, which streamlines network operations. The structure supports fusionfiber technology, which enhances connectivity and efficiency. Hybrid enclosures accommodate various jointbox configurations, allowing flexibility in network design. The integration of splicing and patching functions reduces the need for additional equipment.

Typical Applications

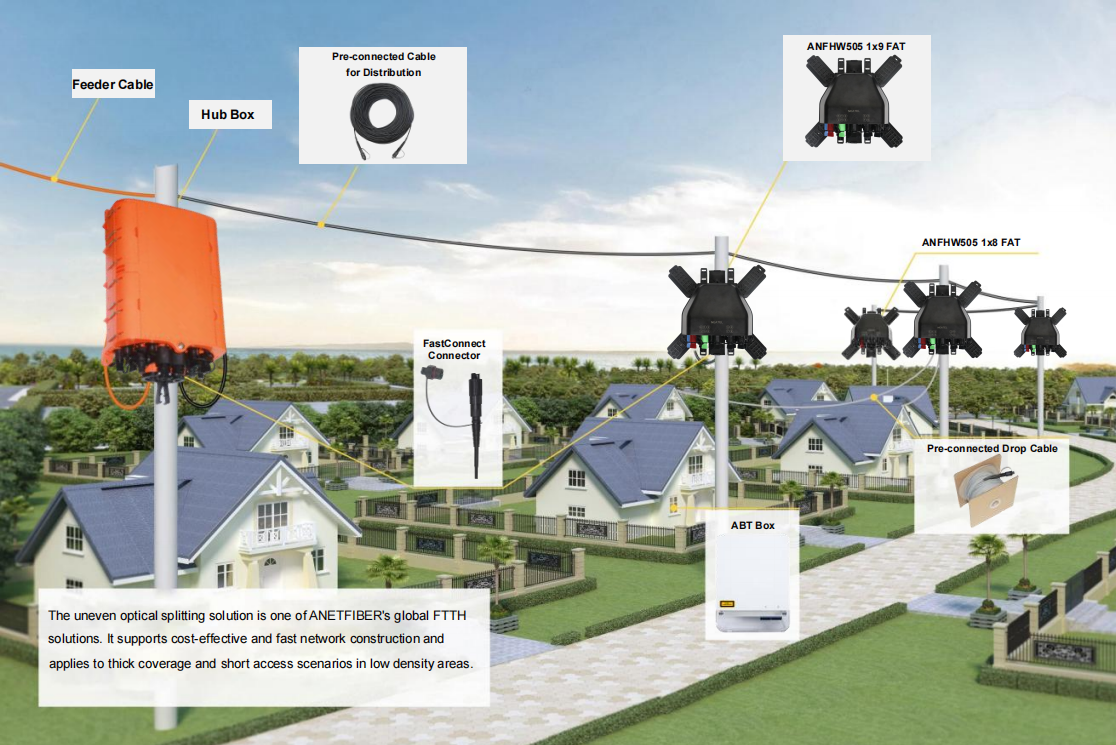

Hybrid fiber enclosures serve as an ideal solution for Fiber to the Home (FTTH) networks. The design supports drop cables to individual locations, enhancing service delivery. Network operators utilize hybrid enclosures in residential areas, where efficient splicingfiber management is essential. The design also suits commercial settings, where high-speed opticalsignal transmission is necessary. Hybrid enclosures facilitate seamless integration of new technologies, such as 5G and IoT, into existing networks.

Features of Fiber Optic Splice Closures

Material and Durability

Weather Resistance

Fiber optic splice closures must withstand various environmental conditions. Manufacturers use materials like high-density polyethylene or stainless steel to ensure durability. These materials resist UV radiation, moisture, and temperature fluctuations. The robust construction protects fiber optic cables from environmental damage. This protection ensures reliable network performance.

Impact Resistance

Impact resistance is crucial for fiber optic splice closures. Strong materials prevent damage from physical forces. The design includes reinforced structures to absorb shocks. This feature maintains the integrity of the fiber optic connections. Network reliability improves with impact-resistant closures.

Capacity and Scalability

Number of Splices Supported

Fiber optic splice closures vary in capacity. Some closures support a limited number of splices. Others accommodate hundreds of splices. The choice depends on network requirements. High-capacity closures suit large-scale installations. Smaller closures fit localized networks.

Expansion Options

Scalability is vital for growing networks. Fiber optic splice closures offer expansion options. Modular designs allow easy upgrades. Additional trays or modules increase capacity. This flexibility supports future network growth. Efficient scalability reduces long-term costs.

Applications and Considerations

Environmental Considerations

Installation Environment

Fiber optic splice closures require careful consideration of the installation environment. Urban areas often present challenges such as limited space and potential interference from other infrastructure. Rural settings may involve exposure to harsh weather conditions. The choice of closure must align with the specific environmental demands. Horizontal closures suit urban installations due to their compact design. Vertical closures excel in rural or buried applications where protection from elements is crucial.

Maintenance Requirements

Maintenance requirements play a significant role in the selection of fiber optic splice closures. Regular inspections ensure the integrity of splicing connections. Easy access to the closure facilitates efficient maintenance procedures. Horizontal designs offer convenient access for technicians, making them ideal for environments needing frequent maintenance. Vertical closures may require more effort for access but provide superior protection in challenging conditions.

Cost and Efficiency

Initial Investment

The initial investment in fiber optic splice closures varies based on design and capacity. High-capacity closures demand a higher upfront cost. Smaller closures offer a cost-effective solution for localized networks. The choice of material also influences the initial investment. Durable materials like stainless steel increase costs but enhance longevity. Network planners must balance cost with performance requirements.

Long-term Benefits

Long-term benefits of fiber optic splice closures include enhanced network reliability and reduced maintenance costs. Durable closures minimize the risk of damage and service interruptions. Impact-resistant designs protect against physical forces, ensuring consistent performance. Scalability options support future network expansion without significant additional investment. Efficient closures contribute to overall cost savings and improved service quality over time.

Choosing the right fiber optic splice closure is vital for network integrity. The appropriate closure ensures protection and organization of splices and cables. This choice directly impacts network performance and reliability. Each network has specific needs that require careful consideration when selecting closures. The right decision enhances efficiency and longevity. Network planners must evaluate environmental conditions and capacity requirements. The investment in suitable closures results in long-term benefits and reduced maintenance costs.

See Also

What Makes Fiber Optic Splice Closures Essential?

Choosing the Right Data Center Solutions: Key Factors to Consider

Understanding Different Types of MPO Breakout Cables

About US

Follow Us

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586