Understanding the Differences Between FBT and PLC Splitters

Fiber optic splitters play a crucial role in telecommunications and data transmission. These devices divide an optical signal into multiple signals, enabling efficient network distribution. Choosing the right splitter, whether it's an FBT splitter, PLC splitter, ABS splitter, or cassette splitter, impacts network performance and reliability. Two common types of splitters are FBT splitters and PLC splitters. FBT splitters, known for their cost-effectiveness and reliability, are constructed by fusing and tapering fibers. PLC splitters, fabricated using semiconductor technology, offer superior performance in terms of insertion loss, bandwidth, and scalability. Additionally, iberdrop cables are often used in conjunction with these splitters to enhance fiber optic network efficiency.

Definitions and Basic Information

What are FBT Splitters?

Construction and Working Principle

FBT splitters, or Fused Biconical Taper splitters, use a method where fibers get fused and tapered together. This process involves heating the fibers until they melt and then pulling them to form a single fiber with multiple outputs. The construction of an FBT splitter includes a primary fiber that splits into several secondary fibers. The tapering process ensures that light distributes evenly among the output fibers.

Common Applications

FBT splitters find applications in various sectors due to their cost-effectiveness. Telecommunications networks often use FBT splitters for basic signal distribution. Data centers also employ these splitters for internal network setups. Industrial applications benefit from the reliability and simplicity of FBT splitters. These splitters support configurations like 1×2, 2×2, 1×16, and 1×7, making them versatile for different needs.

What are PLC Splitters?

Construction and Working Principle

PLC splitters, or Planar Lightwave Circuit splitters, utilize semiconductor technology for their construction. The manufacturing process involves creating waveguides on a silica glass substrate. This method allows for precise control over the splitting ratio and ensures uniform distribution of light. PLC splitters can handle higher split ratios compared to FBT splitters, making them suitable for more complex network setups.

Common Applications

PLC splitters excel in environments requiring high performance and reliability. Fiber optic networks, especially those in telecommunications, frequently use PLC splitters. These splitters also play a crucial role in Fiber to the Home (FTTH) and Passive Optical Networks (PON). Data centers benefit from the superior performance of PLC splitters in terms of insertion loss and bandwidth. Standard configurations for PLC splitters include 1×8, 1×32, and 2×64, catering to large-scale network requirements.

Comparative Analysis

Construction

Materials Used

FBT splitters utilize materials such as fused silica and doped fibers. The primary fiber gets fused with secondary fibers to create multiple outputs. The process involves heating the fibers until they melt. PLC splitters, on the other hand, use semiconductor materials. Silica glass substrates form the waveguides. The choice of materials impacts the performance and durability of the splitters.

Manufacturing Process

The manufacturing process for FBT splitters involves fusing and tapering fibers. This method requires precision to ensure even light distribution. The process can be labor-intensive. PLC splitters use photolithographic techniques. These techniques allow for precise control over the splitting ratio. The waveguides get etched onto the silica substrate. This method ensures uniform light distribution and higher split ratios.

Performance

Insertion Loss

Insertion loss measures the signal loss when light passes through the splitter. FBT splitters generally exhibit higher insertion loss compared to PLC splitters. The manufacturing process of FBT splitters can lead to inconsistencies. PLC splitters offer lower insertion loss due to their precise construction. This makes PLC splitters more suitable for high-performance applications.

Splitting Ratio

The splitting ratio indicates how the optical signal divides among the output ports. FBT splitters support configurations like 1×2, 2×2, and 1×16. The splitting ratio can vary, leading to uneven signal distribution. PLC splitters provide more uniform splitting ratios. Standard configurations include 1×8, 1×32, and 2×64. This uniformity enhances network performance and reliability.

Wavelength Dependence

Wavelength dependence refers to the splitter's ability to handle different wavelengths. FBT splitters operate effectively at specific wavelengths such as 850 nm, 1310 nm, and 1550 nm. PLC splitters offer a broader wavelength range. This feature makes PLC splitters more versatile for various applications. The wider wavelength range ensures better compatibility with different network setups.

Cost

Initial Investment

FBT splitters are generally less expensive. The simpler manufacturing process reduces production costs. This cost-effectiveness makes FBT splitters attractive for basic applications. PLC splitters require a higher initial investment. The advanced manufacturing techniques contribute to the higher cost. However, the superior performance justifies the investment in many cases.

Maintenance Costs

Maintenance costs for FBT splitters can be higher. The sensitivity to temperature changes and mechanical stress increases the likelihood of failures. Regular maintenance may be necessary to ensure optimal performance. PLC splitters, while more expensive initially, offer better reliability. The robust construction reduces the need for frequent maintenance. This can result in lower long-term costs.

Technical Parameters

Operating Temperature Range

FBT splitters and PLC splitters exhibit different operating temperature ranges. FBT splitters work effectively within a narrower range, typically from -5°C to 75°C. This sensitivity to temperature fluctuations can impact performance in environments with extreme temperatures. On the other hand, PLC splitters offer a broader operating temperature range, from -40°C to 85°C. This wider range makes PLC splitters more suitable for diverse environmental conditions, including outdoor applications and harsh industrial settings.

Reliability and Durability

The reliability and durability of fiber optic splitters play a crucial role in network performance. FBT splitters, while cost-effective, tend to be more sensitive to mechanical stress and temperature variations. This sensitivity can lead to higher failure rates, especially in configurations with increased split ratios. Regular maintenance may be necessary to ensure optimal performance. In contrast, PLC splitters provide superior reliability and durability. The robust construction and advanced manufacturing techniques reduce the likelihood of failures. PLC splitters maintain consistent performance even in demanding conditions, making them ideal for high-reliability applications such as telecommunications and data centers.

Advantages and Disadvantages

FBT Splitters

Pros

FBT splitters offer several advantages. The cost-effectiveness of FBT splitters makes them an attractive option for basic applications. The simpler manufacturing process reduces production costs, making FBT splitters affordable. The reliability of FBT splitters in stable environments ensures consistent performance. FBT splitters support various configurations, such as 1×2, 2×2, and 1×16, providing flexibility for different network setups. The use of fused silica and doped fibers contributes to the durability of FBT splitters.

Cons

FBT splitters also have some disadvantages. The sensitivity of FBT splitters to temperature changes can impact performance. Operating within a narrower temperature range, typically from -5°C to 75°C, limits their use in extreme conditions. The higher insertion loss compared to PLC splitters can affect signal quality. The mechanical stress sensitivity of FBT splitters increases the likelihood of failures. Regular maintenance may be necessary to ensure optimal performance, leading to higher long-term costs.

PLC Splitters

Pros

PLC splitters provide numerous benefits. The superior performance of PLC splitters in terms of insertion loss and bandwidth makes them ideal for high-performance applications. The advanced manufacturing techniques ensure precise control over the splitting ratio, resulting in uniform light distribution. The broader operating temperature range, from -40°C to 85°C, allows PLC splitters to function effectively in diverse environmental conditions. The robust construction of PLC splitters enhances reliability and durability, reducing the need for frequent maintenance. PLC splitters support higher split ratios, such as 1×8, 1×32, and 2×64, making them suitable for complex network setups.

Cons

PLC splitters have some drawbacks. The initial investment for PLC splitters is higher due to the advanced manufacturing process. This higher cost may not be justifiable for basic applications. The complexity of the manufacturing process can lead to longer production times. Despite the superior performance, the higher initial cost may limit the adoption of PLC splitters in budget-constrained projects.

FBT splitters and PLC splitters each offer distinct advantages and limitations. FBT splitters provide cost-effective solutions for basic applications, while PLC splitters excel in high-performance environments due to superior insertion loss and bandwidth capabilities. For telecommunications networks requiring high reliability and durability, PLC splitters prove more suitable. Conversely, FBT splitters serve well in stable environments with less demanding requirements. Choosing between these splitters depends on specific network needs, budget constraints, and performance expectations. Both types play crucial roles in enhancing fiber optic network efficiency.

See Also

How to Choose Reliable Fiber Splice Closures

MPO Cable Assemblies for Modern Data Centers

What Are Distribution Boxes and Their Functions in Fiber Optics

Selecting the Right IP68 Waterproof Connectors for Telecom Use

Choosing the Right Fiber Optic Distribution Box for Your Needs

About US

Follow Us

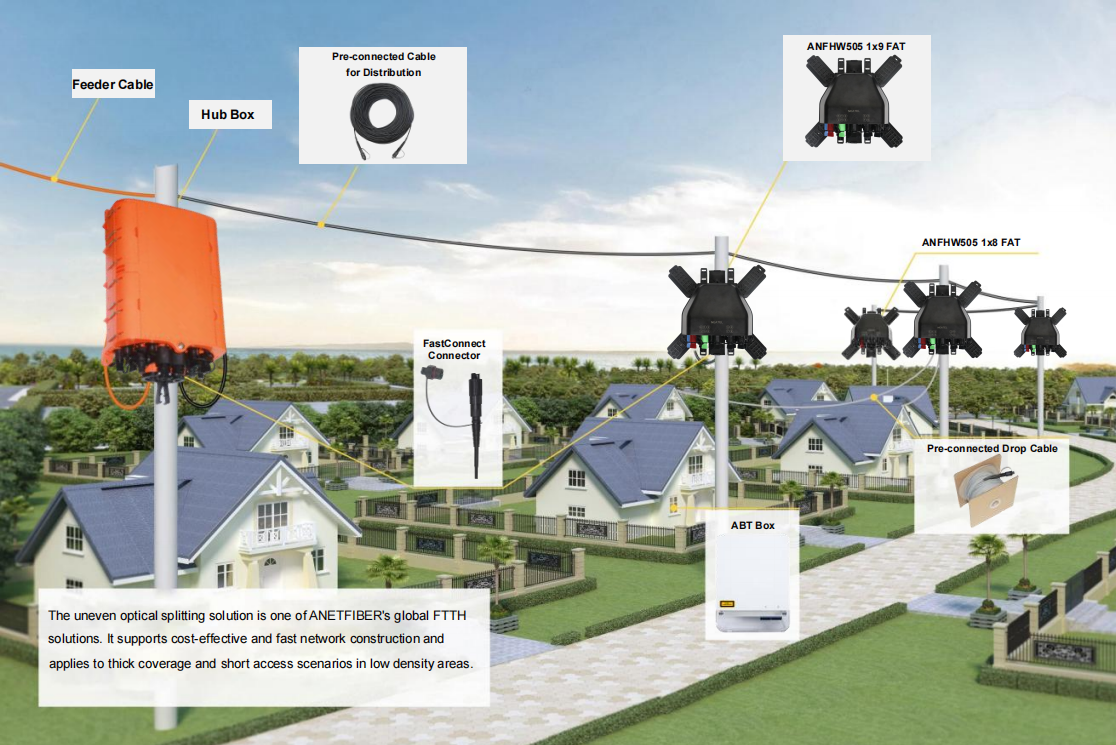

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586