Understanding ADSS Cable and Fiber Optic Strength Member Solutions

Understanding ADSS Cable and Fiber Optic Strength Member Solutions

Importance of Strength Members

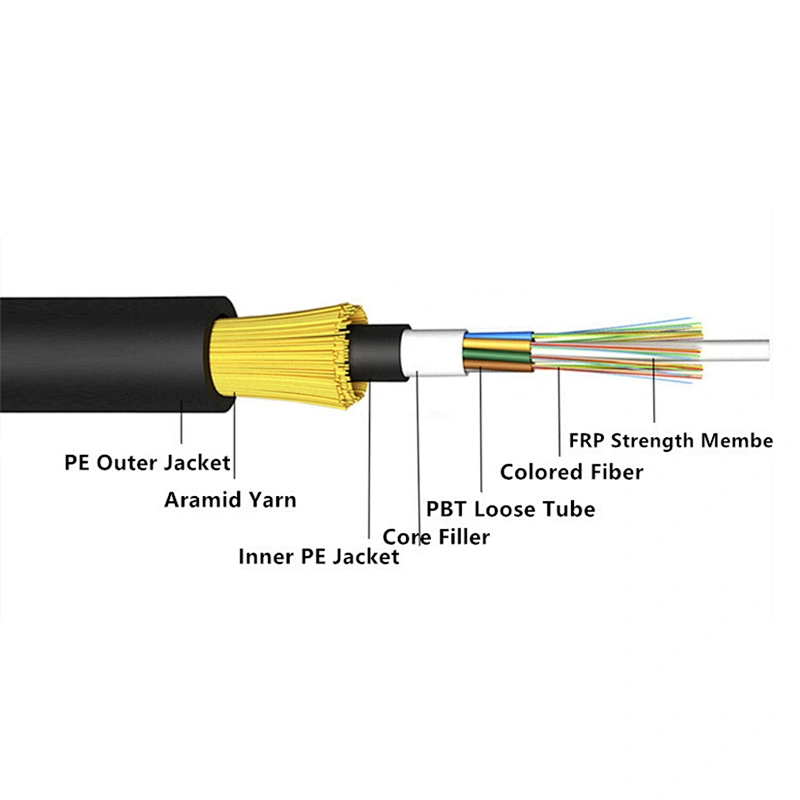

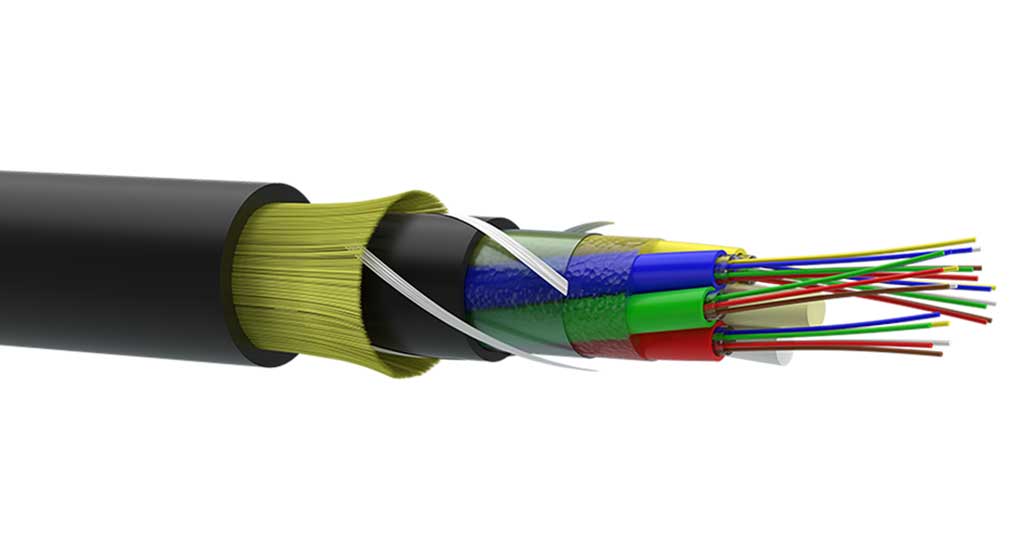

Fiber optic strength member solutions, such as the all-dielectric self-supporting (ADSS) cable, play a crucial role in ensuring the reliability and performance of network infrastructures. These strength members provide vital support and protection to the delicate fiber optic cables, safeguarding them against environmental factors and mechanical stress. The selection of appropriate materials for strength members, including aramid yarn, fiberglass, and steel, is essential to meet the specific requirements of fiber optic cable constructions. Proper integration of these components ensures the longevity and durability of the entire network system.

Strength Member Solutions

Importance of Fiber Optic Strength Members

In the realm of fiber optic cable construction, the significance of strength members cannot be overstated. These components serve the crucial purpose of providing essential support and protection to the delicate fiber optic cables. By withstanding environmental elements and mechanical stress, strength members ensure the integrity and longevity of the entire network infrastructure. Different types of strength members are utilized in fiber optic cable construction, each tailored to meet specific requirements and environmental conditions.

Diverse Materials for Strength Members

The materials used for strength members encompass a range of options to accommodate varying needs. Common materials include aramid yarn, fiberglass, and steel, each offering distinct advantages based on the specific demands of the cable. The choice of material is a critical consideration in ensuring that the strength member effectively reinforces and protects the fiber optic cables within different installation environments.

Fiber Optic Cable Construction

Core Components

Fiber optic cable construction involves several core components that are essential for its functionality. The core of the cable is where the light signals travel, enabling data transmission. Surrounding the core is the cladding, which helps to contain the light within the core by reflecting it inward. Additionally, a buffer coating provides further protection to the core and cladding, enhancing the overall durability of the cable.

Manufacturing Process

The manufacturing process of fiber optic cables is a meticulous procedure that requires attention to detail. It involves carefully assembling the core, cladding, and strength members in a controlled environment to ensure optimal performance and longevity. During this process, each component must be integrated seamlessly to guarantee the cable's durability and reliability in various environmental conditions.

By incorporating high-quality materials and precision engineering, manufacturers can produce fiber optic cables that meet stringent performance standards and offer reliable data transmission capabilities.

ADSS Cable Advantages

Durability and Reliability

When it comes to outdoor installations, ADSS cable offers unparalleled durability and reliability. The all-dielectric construction of ADSS cables provides exceptional resistance to environmental factors, ensuring longevity and consistent performance in challenging outdoor conditions. This makes them particularly well-suited for deployment in areas prone to harsh weather or extreme temperatures. The robust design of ADSS cables minimizes the risk of signal interruptions, making them a dependable choice for maintaining network connectivity in diverse climates.

Installation Flexibility

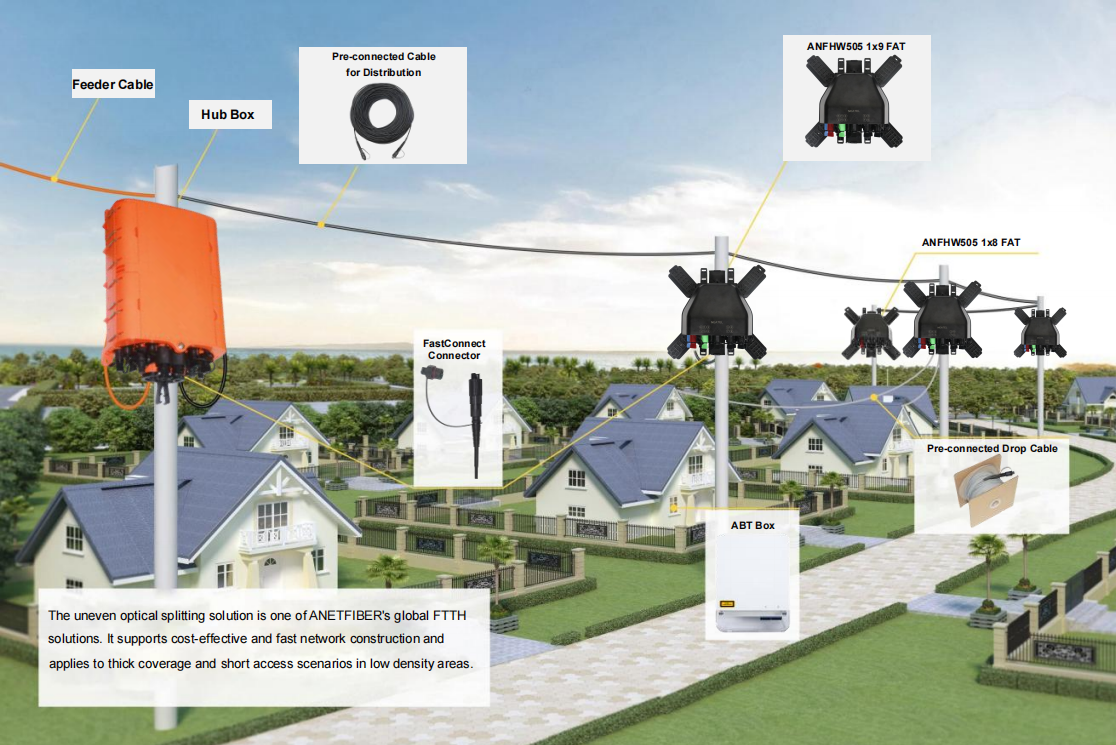

One of the notable advantages of ADSS cables is their remarkable installation flexibility. Unlike traditional cables, ADSS cables can be conveniently installed on existing poles without the need for additional support structures. This feature streamlines the installation process, significantly reducing both time and costs associated with setting up fiber optic networks. The ability to leverage existing infrastructure for deployment makes ADSS cables an efficient and cost-effective solution for expanding network coverage and capacity.

By harnessing the durability, reliability, and installation flexibility offered by ADSS cable, network operators can effectively enhance their infrastructure's performance while optimizing resource utilization.

Comparing Fiber Optic Cables

ADSS vs. Other Cable Types

When comparing ADSS cables with traditional aerial cables and underground cables, several key differences come to light. Traditional aerial cables require additional support structures such as messenger wires for installation, adding complexity and time to the deployment process. In contrast, ADSS cables can be directly installed on existing poles, eliminating the need for supplemental support systems. This streamlined installation not only reduces deployment time but also minimizes material and labor costs.

In terms of underground cables, the excavation and trenching required for their installation can result in significant disruptions and expenses. ADSS cables offer a more efficient alternative, as they can be deployed without extensive ground disturbance. This makes them particularly advantageous in urban areas where minimizing disruptions is essential.

Performance and Cost Considerations

The performance and cost-effectiveness of ADSS cables compared to other options are significant factors in network infrastructure planning. When evaluating performance, ADSS cables demonstrate exceptional resistance to environmental factors, ensuring reliable data transmission even in challenging outdoor conditions. Additionally, their all-dielectric construction eliminates the need for grounding, simplifying installation requirements.

From a cost perspective, considerations such as maintenance, longevity, and installation costs play a crucial role in decision-making. The durability of ADSS cables reduces the need for frequent maintenance, contributing to long-term cost savings. Furthermore, their efficient installation process translates to reduced labor expenses and faster network expansion.

ADSS Cable Overview

ADSS cables, also known as all-dielectric self-supporting cables, provide robust solutions for fiber optic networks. Their innovative design incorporates fiber optic strength member solutions to ensure reliable performance and durability. Understanding the advantages of ADSS cables is essential for network construction and deployment, as they offer exceptional resistance to environmental factors and mechanical stress. The all-dielectric construction eliminates the need for grounding, simplifying installation requirements and reducing overall costs.

See Also

Comparing the Advantages of FRP and Steel for ADSS Cable: A Comprehensive Guide

Maximizing Cost-Effectiveness with Quick Assembly Connectors for Round Drop Cables

Exploring Balanced and Unbalanced PLC Splitters in Telecommunication Infrastructure

Understanding ABS Module: A Key Component for FTTH Applications

Exploring the Options for Preconnectorized Drop Cables with SC APC Connectors in White Color

About US

Follow Us

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586