The Ultimate Guide to PLC Cassette Modules: Types, Features, and Future Trends

PLC Cassette Modules: An Overview

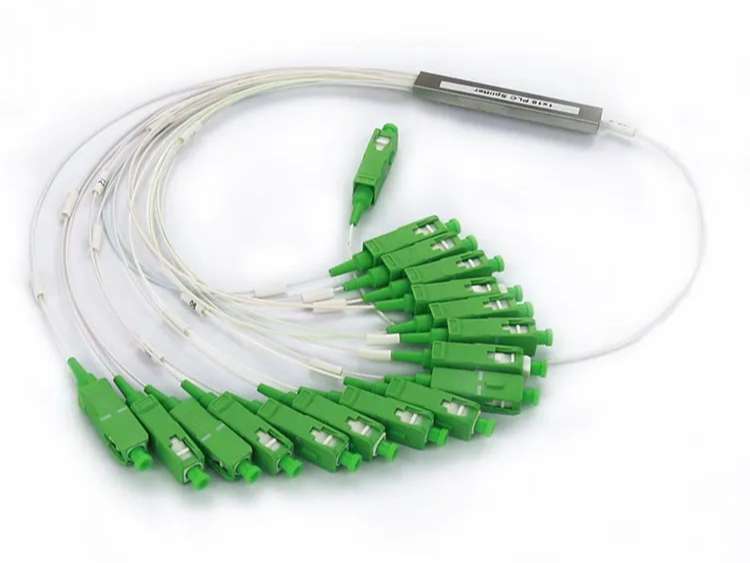

PLC cassette modules are essential components in the field of telecommunications, playing a crucial role in signal distribution and network connectivity. These compact devices are designed to efficiently manage and distribute optical signals within fiber optic networks. Also known as fiber optic cassette modules, PLC cassettes offer a convenient and modular solution for organizing and routing optical fibers.

By incorporating advanced technology, PLC cassette modules enable the splitting and combining of optical signals with minimal loss or distortion. They provide a reliable means of optimizing network performance while ensuring efficient transmission of data across various communication channels.

In this comprehensive guide, we will explore the different types, features, and future trends of PLC cassette modules. From understanding their unique characteristics to discussing installation considerations and troubleshooting tips, this guide aims to equip technical professionals, network engineers, and telecommunications enthusiasts with the knowledge needed to make informed decisions regarding PLC cassette modules.

Exploring Different Types of ABS Splitter Boxes

ABS splitter boxes are commonly used in telecommunications networks to facilitate the distribution of optical signals. These compact devices are available in various types, each with unique characteristics and specifications. Understanding the different options can help professionals choose the most suitable ABS splitter box for their specific application.

Understanding ABS Splitter Boxes

ABS splitter boxes, also known as fiber optic splitter boxes or PLC splitter boxes, are essential components in telecommunications infrastructure. They are designed to split or combine optical signals, allowing for efficient signal distribution and network connectivity. These boxes house the necessary components and connectors to manage multiple fiber optic cables.

Comparing Different Types of ABS Splitter Boxes

There is a wide range of ABS splitter box models available on the market, each offering its own advantages and applications. Some common types include:

Rack-Mount ABS Splitter Boxes: These boxes are designed to be mounted on standard equipment racks, providing a centralized solution for managing large-scale fiber optic networks.

Wall-Mount ABS Splitter Boxes: Wall-mountable ABS splitter boxes offer a compact and space-saving option for smaller network installations or areas with limited space.

Outdoor ABS Splitter Boxes: Built to withstand harsh environmental conditions, outdoor ABS splitter boxes provide protection against moisture, dust, and temperature fluctuations.

Indoor ABS Splitter Boxes: Indoor ABS splitter boxes are suitable for indoor installations where environmental factors are not a concern.

Module-Type ABS Splitter Boxes: Module-type ABS splitter boxes offer flexibility by allowing modules to be easily inserted or removed based on network requirements.

By comparing the different types of ABS splitter boxes, professionals can select the appropriate model based on factors such as installation location, scalability needs, environmental conditions, and budget considerations.

Understanding Key Features and Benefits

ABS splitter boxes are designed with various features to enhance performance and provide reliable signal distribution in telecommunications networks. These fiber optic splitter boxes, also known as PLC splitter boxes, offer several key features that contribute to their effectiveness.

Key Features of ABS Splitter Boxes

Compact Design: ABS splitter boxes are compact and lightweight, making them easy to install and manage within network infrastructure.

Multiple Input/Output Ports: These boxes typically have multiple input and output ports, allowing for efficient connectivity with various fiber optic cables.

Low Insertion Loss: ABS splitter boxes are engineered to minimize insertion loss, ensuring minimal signal degradation during the splitting process.

Wide Operating Temperature Range: They can operate reliably across a wide temperature range, making them suitable for different environmental conditions.

Durable Construction: ABS splitter boxes are built with durable materials that provide protection against physical damage and ensure long-term reliability.

Benefits of Using ABS Splitter Boxes

Using ABS splitter boxes offers several advantages for telecommunications networks:

Improved Network Efficiency: By efficiently splitting optical signals, these boxes enable the simultaneous transmission of data to multiple destinations, optimizing network efficiency.

Enhanced Network Reliability: ABS splitter boxes help distribute signals evenly across different paths, reducing the risk of signal loss or disruption and enhancing overall network reliability.

Flexibility in Network Design: With the ability to accommodate multiple input/output ports, these boxes provide flexibility in designing network architectures and adapting to changing requirements.

Cost-Effective Solution: ABS splitter boxes offer a cost-effective solution for signal distribution compared to alternative methods such as individual point-to-point connections.

By leveraging the key features and benefits of ABS splitter boxes, telecommunication professionals can ensure efficient signal distribution while maintaining network reliability.

Tips for Installation, Maintenance, and Troubleshooting

Proper installation, maintenance, and troubleshooting are essential for ensuring optimal performance of ABS splitter boxes in telecommunications networks. By following these tips, professionals can effectively set up, maintain, and resolve issues related to these devices.

Installation of ABS Splitter Boxes

Plan the Installation: Before starting the installation process, carefully plan the placement of ABS splitter boxes to ensure efficient signal distribution and accessibility for future maintenance.

Prepare the Environment: Ensure that the installation environment is clean, dry, and free from any potential sources of damage or interference.

Handle with Care: When handling ABS splitter boxes, avoid excessive bending or twisting of fiber optic cables to prevent signal loss or damage.

Proper Cable Management: Organize and manage fiber optic cables neatly within the box to minimize signal interference and facilitate future maintenance.

Maintenance and Care

Regular Inspection: Conduct routine inspections to check for any physical damage or loose connections within ABS splitter boxes.

Cleaning: Clean the exterior surfaces of the boxes using a soft cloth or brush to remove dust or debris that may affect performance.

Protective Measures: Implement protective measures such as dust covers or protective enclosures to safeguard ABS splitter boxes from environmental factors that could impact their functionality.

Documentation: Maintain detailed records of installations, repairs, and any changes made to ABS splitter boxes for future reference.

Troubleshooting Common Issues

Signal Loss: Check for loose connections or damaged cables within the ABS splitter box. Reconnect or replace components as necessary.

Uneven Signal Distribution: Verify that all input/output ports are functioning correctly and evenly distributing signals across connected fibers.

Interference or Noise: Identify potential sources of interference such as nearby electrical equipment or environmental factors like temperature fluctuations. Take appropriate measures to mitigate interference.

Power Supply Issues: Ensure a stable power supply by checking connections and verifying that power requirements are met.

By following these tips for installation, maintenance, and troubleshooting, professionals can maximize the performance and longevity of ABS splitter boxes in telecommunications networks.

Exciting Future Trends and Cost Considerations

As technology continues to advance, the field of ABS PLC splitter technology is constantly evolving, bringing forth exciting future trends and considerations for cost and affordability.

Future Trends in ABS PLC Splitter Technology

Increased Port Density: Future ABS PLC splitter boxes are expected to offer higher port density, allowing for more efficient signal distribution within telecommunication networks.

Enhanced Performance: Advancements in ABS PLC splitter technology will likely lead to improved performance metrics such as lower insertion loss and higher splitting ratios, ensuring better signal quality and network efficiency.

Integration with Next-Generation Networks: ABS PLC splitters are anticipated to integrate seamlessly with emerging next-generation network technologies such as 5G, enabling faster data transmission speeds and supporting the growing demand for bandwidth.

Miniaturization: The trend towards smaller form factors will continue, resulting in more compact ABS PLC splitter boxes that can be easily integrated into various network architectures.

Cost and Affordability of ABS Splitter Boxes

ABS splitter boxes are available at various price points, offering flexibility in terms of budget considerations. Factors that may affect the cost of these devices include:

Type and Model: Different types and models of ABS splitter boxes may vary in price based on their features, specifications, and capabilities.

Port Count: The number of input/output ports required in an ABS splitter box can impact its cost. Higher port counts generally result in a higher price point.

Quality and Brand: Well-established brands or higher-quality ABS splitter boxes may come with a premium price due to their reputation for reliability and performance.

Market Demand: Market dynamics can influence pricing, with factors such as supply chain availability or market competition affecting the cost of ABS splitter boxes.

It's important to consider both the upfront cost and long-term benefits when evaluating the affordability of ABS splitter boxes for specific telecommunications projects or applications.

Embracing the Future of PLC Cassette Modules

PLC cassette modules are integral to the telecommunications industry, playing a vital role in signal distribution and network connectivity. By understanding the different types, features, and future trends of these fiber optic cassette modules, professionals can make informed decisions when implementing or upgrading their network infrastructure.

Staying updated with the latest advancements in ABS splitter technology is crucial for ensuring efficient network operations. As the field continues to evolve, embracing the future of PLC cassette modules means being prepared to leverage emerging technologies, such as increased port density, enhanced performance, and seamless integration with next-generation networks.

By embracing these advancements and staying informed about the latest developments in ABS splitter technology, professionals can optimize their telecommunications networks for improved efficiency, reliability, and connectivity.

See Also

The Ultimate Guide to MPO Duplex Fiber Connectors: Boost Network Reliability and Speed

The Future of PLC Cassette Modules in FTTH Applications

The Future of CTO Boxes: Exploring the Compatibility and Performance of Huawei Mini SC Connectors

Exploring the Applications of LC SC Duplex Fiber Optic Adapters

About US

Follow Us

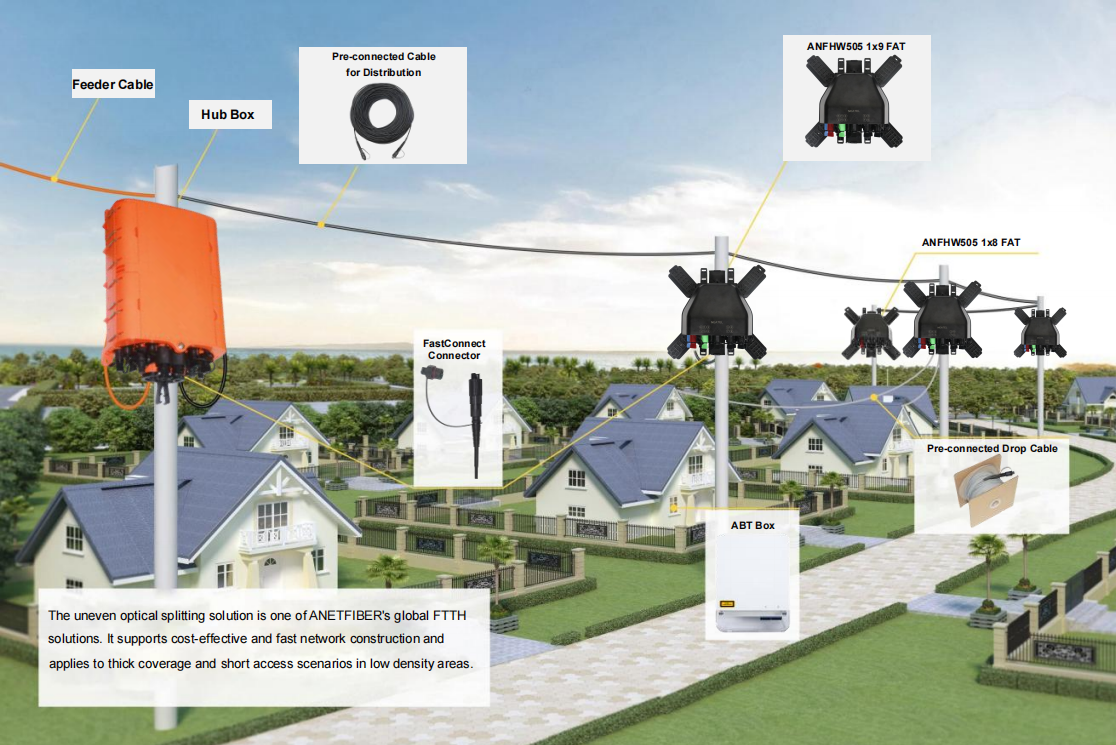

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586