Exploring the Pros and Cons of PLC Blockless Splitters in Fiber Optic Networks

Understanding PLC Blockless Splitters

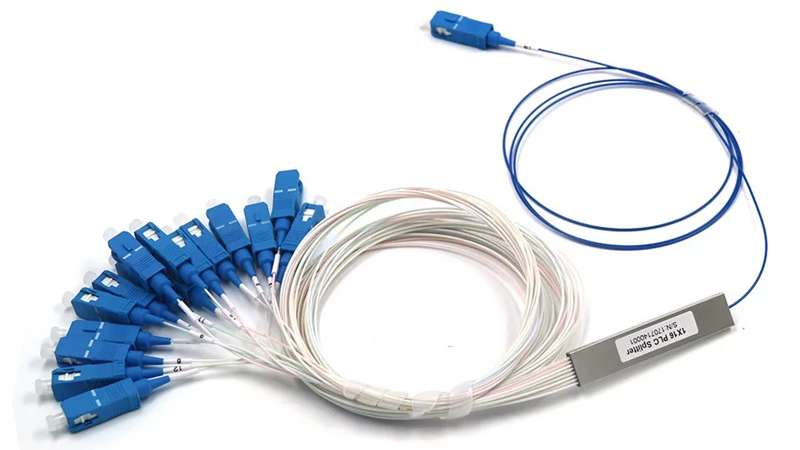

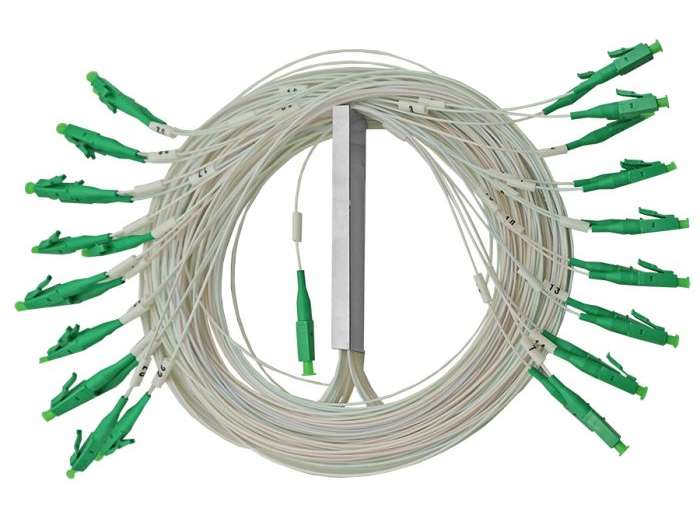

PLC Blockless splitters are essential components in fiber optic networks. They are specifically designed to efficiently split optical signals, allowing for the distribution of data across multiple paths. These splitters offer a range of advantages and disadvantages that need to be explored in order to make informed decisions about their implementation.

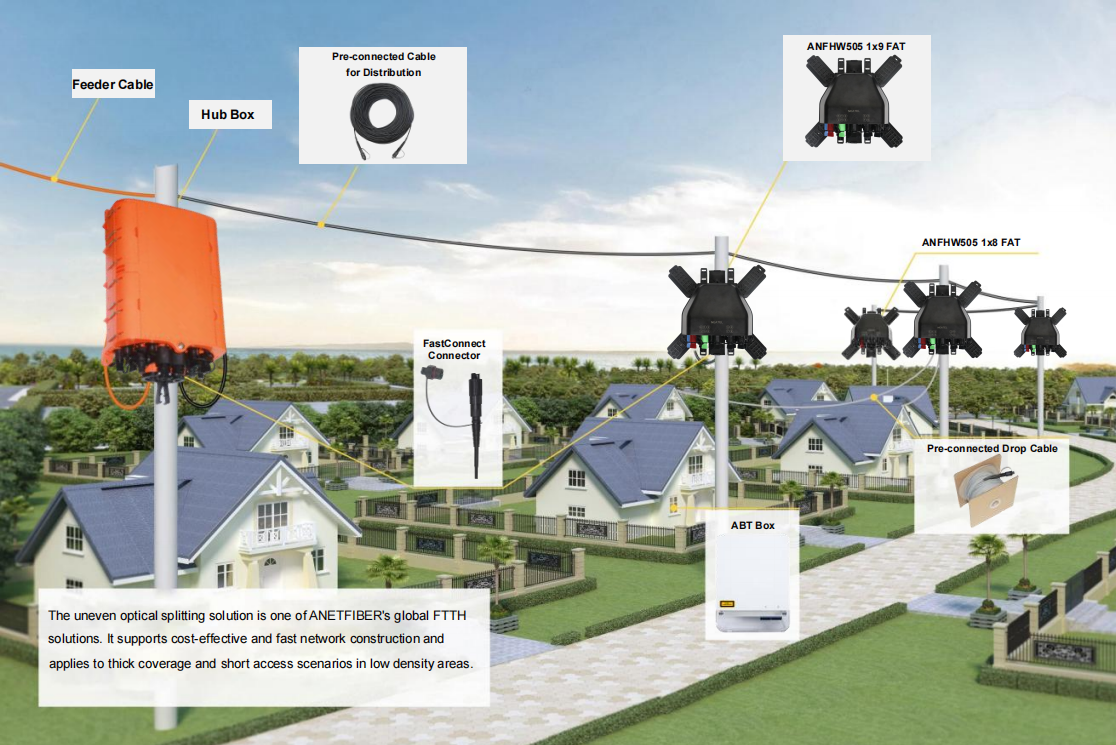

In fiber optic networks, PLC blockless splitters play a crucial role by dividing the optical signal into multiple outputs, enabling it to reach multiple destinations simultaneously. This capability is vital for applications such as Fiber to the Home (FTTH) networks and Passive Optical Network (PON) deployments.

By utilizing these blockless splitters, network engineers can effectively manage and distribute optical signals through fiber optic cables. However, it is important to understand both the benefits and limitations of PLC blockless splitters before incorporating them into a network infrastructure.

Unveiling the Benefits of Fiber Optic PLC Blockless Splitters

Enhanced Signal Distribution

One of the significant advantages of PLC blockless splitters in fiber optic networks is their ability to ensure efficient distribution of optical signals. These splitters are designed to split the incoming signal into multiple outputs, allowing it to be transmitted to different destinations simultaneously. This enhanced signal distribution capability is crucial for applications that require data transmission to multiple endpoints, such as FTTH networks and PON deployments.

Furthermore, PLC blockless splitters provide high-quality and reliable signal transmission. They minimize signal loss and maintain signal integrity throughout the network, ensuring that data is delivered accurately and without degradation. This reliability makes them an ideal choice for critical applications where uninterrupted communication is essential.

Cost-Effective Solution

Blockless splitters offer a cost-effective solution for fiber optic networks. Compared to other types of splitters, such as PLC tube-type or PLC tray-type splitters, blockless splitters are more affordable. Their simpler design and construction contribute to their lower cost while still delivering reliable performance.

By choosing blockless splitters, network engineers can achieve significant cost savings without compromising on functionality or performance. This affordability makes them an attractive option for both small-scale installations and large-scale deployments in fiber optic networks.

Examining the Limitations of Fiber Optic PLC Blockless Splitters

Limited Splitting Ratio

One of the limitations of PLC blockless splitters is their limited splitting ratio. These splitters have a maximum splitting ratio, which determines the number of outputs they can support. While they are suitable for applications that require a moderate number of splits, they may not be ideal for scenarios that demand high splitting ratios.

In situations where a large number of outputs are required, such as in densely populated areas or multi-dwelling units, other types of splitters like PLC tube-type or PLC tray-type splitters may be more appropriate. These alternatives offer higher splitting ratios and can accommodate a greater number of connections.

Lack of Flexibility

Blockless splitters have a fixed configuration, meaning their input and output ports cannot be modified once installed. This lack of flexibility can pose challenges when network requirements change over time. If additional connections or reconfigurations are needed, it may require replacing the existing blockless splitter with one that matches the new requirements.

In contrast, other types of splitters like PLC modular splitters offer more flexibility as they allow for easy module additions or removals without disrupting the entire network infrastructure. This adaptability makes them better suited for networks that anticipate future expansion or frequent changes in connectivity needs.

Despite these limitations, it's important to consider that PLC blockless splitters still provide reliable signal distribution at an affordable cost. The decision to use blockless splitters should be based on the specific requirements and constraints of each fiber optic network installation.

Key Considerations for Selecting a PLC Blockless Splitter

Splitting Ratio Requirements

When selecting a PLC blockless splitter for your fiber optic network, it is crucial to evaluate the required splitting ratio for your specific application. The splitting ratio refers to the number of outputs that can be supported by the splitter. Determine how many connections you need and choose a blockless splitter that meets your splitting ratio needs.

Consider the current and future demands of your network. If you anticipate an increase in the number of connections or expansions in the future, it is advisable to select a blockless splitter with a higher splitting ratio than your current requirements. This will allow room for growth without requiring immediate replacement or upgrades.

Network Scalability

Another important consideration when choosing a PLC blockless splitter is the scalability of your network. Assess whether your network has the potential for future expansion or if there are plans to add more connections in the long run. In such cases, it is essential to select a blockless splitter that allows for easy scalability.

Look for splitters that offer modular designs or options for adding additional modules as needed. These modular splitters provide flexibility and enable you to expand your network without disrupting existing connections. By considering network scalability during the selection process, you can ensure that your fiber optic network can adapt and grow along with changing requirements.

By carefully evaluating splitting ratio requirements and considering network scalability, you can make an informed decision when selecting a PLC blockless splitter for your fiber optic network.

Exploring Applications, Installation, and Maintenance of Fiber Optic PLC Blockless Splitters

Applications of Blockless Splitters

Blockless splitters find widespread use in various applications within fiber optic networks. One common application is in FTTH (Fiber to the Home) networks, where blockless splitters are used to distribute optical signals to individual homes or premises. They play a crucial role in ensuring reliable and efficient connectivity for residential users.

Additionally, blockless splitters are suitable for PON (Passive Optical Network) deployments. In PON architectures, these splitters enable the sharing of optical fibers among multiple subscribers, allowing for cost-effective network designs. They facilitate the delivery of high-speed internet access, voice services, and other data-intensive applications to end-users.

Installation and Maintenance

Proper installation techniques are essential to ensure optimal performance of PLC blockless splitters. It is crucial to follow manufacturer guidelines and industry best practices during installation. This includes proper handling of fiber optic cables, ensuring clean and secure connections, and verifying signal integrity after installation.

Regular maintenance is also vital to maintain signal integrity in fiber optic networks using blockless splitters. Periodic inspections should be conducted to identify any physical damage or degradation that may affect performance. Cleaning connectors and inspecting splices can help prevent signal loss or disruptions.

Network operators should establish maintenance schedules and protocols to ensure timely inspections and repairs if necessary. By proactively addressing maintenance needs, they can minimize downtime and optimize the overall performance of their fiber optic network.

Looking Ahead: Future Trends in PLC Blockless Splitters

Advancements in Technology

Ongoing research and development efforts are focused on improving the performance of PLC blockless splitters. As technology continues to evolve, new advancements may lead to enhanced functionality and efficiency of these splitters. Researchers are exploring innovative designs, materials, and manufacturing techniques to optimize their performance.

Advancements in technology may result in improved splitting ratios, allowing for more connections without sacrificing signal quality. Additionally, developments in materials and fabrication processes could lead to reduced insertion loss and better overall performance of blockless splitters.

Furthermore, advancements in integrated optics and photonics technologies may enable the integration of additional functionalities into blockless splitters. This could include features like wavelength division multiplexing (WDM) or power monitoring capabilities, enhancing the versatility and value of these devices.

Increasing Demand

The demand for PLC blockless splitters is expected to rise significantly in the coming years. With the increasing deployment of fiber optic networks worldwide, there is a growing need for advanced splitters that can efficiently distribute optical signals. The proliferation of applications such as high-speed internet access, video streaming, cloud computing, and Internet of Things (IoT) devices is driving the demand for higher capacity networks.

As fiber optic networks continue to expand and reach more areas globally, the demand for reliable and cost-effective solutions like blockless splitters will continue to grow. Network operators are seeking efficient ways to manage optical signals while keeping costs under control.

To meet this increasing demand, manufacturers are likely to invest in research and development efforts to further improve the performance and affordability of PLC blockless splitters.

Wrapping Up: Pros and Cons of PLC Blockless Splitters

PLC Blockless splitters offer significant advantages in terms of enhanced signal distribution and cost-effectiveness. They play a crucial role in efficiently distributing optical signals in fiber optic networks, ensuring reliable connectivity for various applications. These splitters provide a cost-effective solution without compromising on performance.

However, it is important to consider the limitations of PLC blockless splitters, such as their limited splitting ratios and lack of flexibility. Depending on the specific requirements of your network, alternative splitter options may be more suitable.

When selecting blockless splitters, it is essential to consider key factors such as splitting ratio requirements and network scalability. Additionally, staying informed about future trends and advancements in this technology can help make informed decisions that align with evolving network needs.

In conclusion, PLC blockless splitters offer valuable benefits but should be chosen carefully based on individual network requirements and considerations.

See Also

The Future of PLC Cassette Modules in FTTH Applications

The Future of Fiber Preconnection Solutions: Exploring MTP-LC Duplex 12cores Trunk Cable Patchcord

The Future of CTO Boxes: Exploring the Compatibility and Performance of Huawei Mini SC Connectors

Choosing the Best Fiber Optic Splitters: The ABS PLC Advantage

The Ultimate Guide to HDMI Cables: Function, Importance, and Future Developments

About US

Follow Us

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586