The Future of Preconnection Solutions: Exploring Features, Applications, and Technology

The Future of Preconnection Solutions

As technology continues to advance, the future of preconnection solutions looks promising. These innovative solutions offer numerous benefits and applications in the field of cable systems. By exploring preconnected cable systems, professionals, engineers, technicians, and enthusiasts can unlock their potential for efficient installation and maintenance processes. Preconnected cables provide a cost-effective and efficient solution for various industries, enhancing overall efficiency. Understanding the underlying technology driving preconnection solutions is crucial to harnessing their full potential. By staying updated with advancements in preconnection technology, professionals can anticipate future developments and trends that will shape the industry.

Exploring Features and Applications

Preconnected cable systems offer a range of benefits that make them highly advantageous in various industries. One of the key advantages is their efficient installation and maintenance processes. With preconnected cables, professionals can save time and effort by eliminating the need for on-site terminations. This streamlined process not only reduces installation time but also minimizes the risk of errors or faulty connections.

Another significant benefit is the cost-effectiveness and improved efficiency that preconnected cable systems bring. By utilizing preconnection solutions, companies can optimize their resources and reduce labor costs associated with cable installations. Additionally, these systems enhance overall efficiency by providing reliable connections that minimize signal loss and ensure optimal performance.

The wide range of applications across various industries is another notable feature of preconnected cable systems. From telecommunications to industrial automation, preconnected cables find uses in diverse fields. They are commonly employed in data centers, manufacturing facilities, healthcare settings, transportation systems, and more. The versatility of preconnection solutions makes them an ideal choice for different industry requirements.

When it comes to types of preconnection solutions, there are several options available. Plug-and-play preconnected cables are a popular choice due to their ease of use and quick deployment capabilities. These cables come ready-to-use with connectors already attached, allowing for hassle-free installations.

Preconnected cable assemblies with different connectors provide flexibility in connecting various devices or equipment within a system. These assemblies can be customized to meet specific requirements by incorporating different connector types such as USB, HDMI, Ethernet, or fiber optic connectors.

For unique or specialized applications, customizable preconnection solutions offer tailored options to suit specific needs. These solutions allow for customization in terms of cable length, connector types, and other specifications based on the project's requirements.

Understanding the Technology Behind Preconnection Solutions

Preconnection technology relies on several key components to ensure reliable and efficient cable systems. Connectors play a crucial role in preconnected cable systems, as they enable the seamless connection between cables and devices. Compatibility between connectors is essential to ensure proper functionality and signal transmission. Manufacturers invest in research and development to create connectors that are compatible with a wide range of devices, ensuring versatility and ease of use.

Advanced cable termination techniques are another vital component of preconnection technology. These techniques involve precise methods for attaching connectors to cables, ensuring secure connections that can withstand various environmental conditions. Techniques such as crimping, soldering, or fusion splicing are employed based on the type of cable and connector being used.

Quality control and testing processes are integral to maintaining the reliability of preconnected cable systems. Manufacturers implement rigorous quality control measures at every stage of production to ensure that each cable assembly meets industry standards. Testing processes include checks for signal integrity, durability, and performance under different conditions. These stringent measures help identify any potential issues early on and ensure that only high-quality preconnected cables reach the market.

Advancements in preconnection technology continue to drive innovation in the field. Miniaturization has been a significant trend, allowing for smaller connectors and more compact cable assemblies without compromising performance. This enables greater flexibility in tight spaces or applications where size constraints exist.

Integration with IoT (Internet of Things) and smart devices is another area where preconnection technology is evolving. As more devices become interconnected, preconnected cables play a crucial role in establishing reliable connections within these complex networks. Future developments may include enhanced compatibility with emerging technologies and improved data transmission capabilities.

Future Developments and Trends

As preconnection solutions continue to evolve, they are expected to find emerging applications in various industries. One such area is the integration of preconnected cable systems with renewable energy systems. The renewable energy sector is rapidly growing, and preconnection solutions can play a vital role in establishing reliable connections between solar panels, wind turbines, and other renewable energy sources. This integration can enhance overall efficiency and contribute to the development of sustainable energy solutions.

Another emerging trend is the use of preconnected cable solutions for smart cities. As cities become more connected and technologically advanced, the demand for efficient and reliable cable systems increases. Preconnected cables can provide seamless connectivity for various smart city applications such as intelligent transportation systems, smart grids, public safety networks, and more. These solutions enable faster deployment of infrastructure while ensuring optimal performance.

Advancements in data centers and telecommunications also drive future developments in preconnection technology. With increasing data demands, there is a need for higher data transmission speeds and improved reliability. Preconnected cable systems can meet these requirements by providing high-speed connections that support the growing demand for bandwidth-intensive applications.

Enhancements in preconnection technology will focus on increasing data transmission speeds to accommodate the ever-increasing volume of data being transferred. Improved durability and reliability will ensure that preconnected cables can withstand harsh environmental conditions without compromising performance or signal integrity.

Standardization and compatibility across industries are crucial factors that will shape future trends in preconnection solutions. Efforts are being made to establish industry standards that promote interoperability between different manufacturers' products. This standardization will enable seamless integration of preconnected cables across various industries, ensuring compatibility and ease of use.

The Way Forward for Preconnection Solutions

Preconnection solutions are revolutionizing cable systems, offering efficient installation processes, cost-effectiveness, and improved efficiency. Continuous advancements in preconnected cable technology will shape the future of this industry, with miniaturization, integration with IoT devices, and increased data transmission speeds being key areas of development. It is essential for professionals, engineers, technicians, and enthusiasts to stay updated with the latest developments in preconnection solutions to leverage their benefits fully. By embracing these innovative technologies and keeping pace with emerging trends, individuals can harness the power of preconnected cable systems to drive efficiency and connectivity across various industries.

See Also

The Future of CTO Boxes: Exploring the Compatibility and Performance of Huawei Mini SC Connectors

MU Fiber Optic Pigtails: Key Features and Benefits for Network Engineers

Discover the Benefits of SN Mini BTW Connectors | Fiber Adapter

Exploring the Applications of LC SC Duplex Fiber Optic Adapters

Understanding Different Types of Fiber Optic Adapters: A Comprehensive Guide

About US

Follow Us

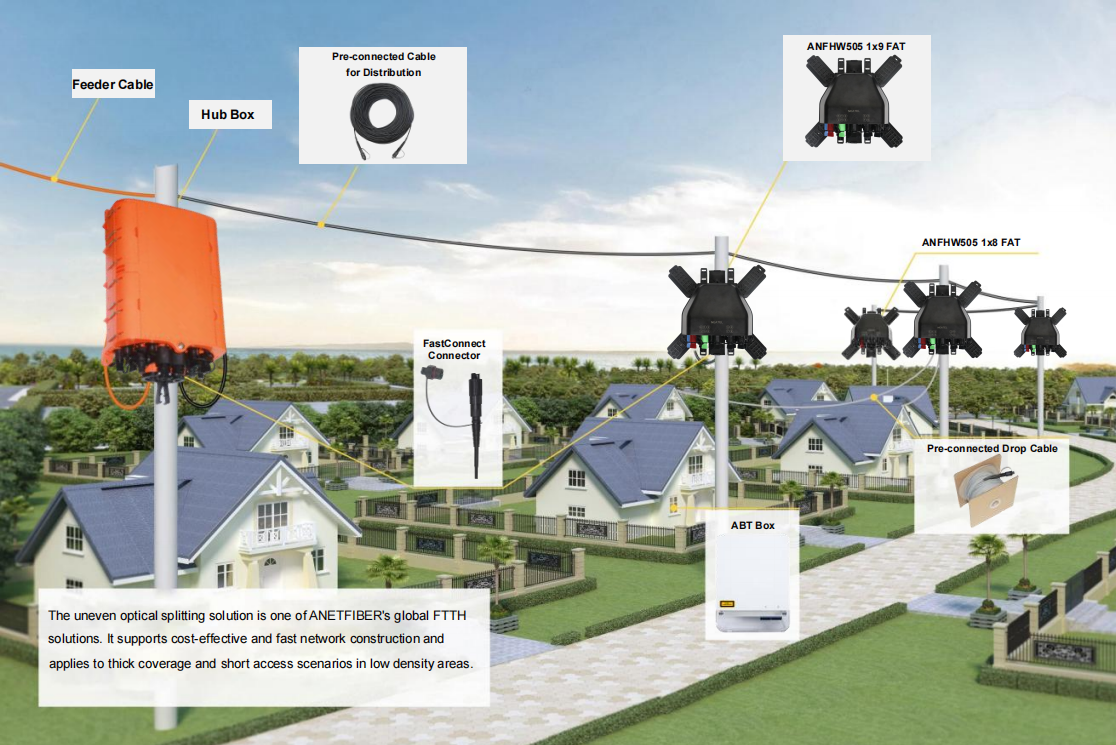

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586