The Future of Fiber Optic Cable Splice Closures: Trends and Innovations

Unleashing the Potential

In the ever-evolving world of telecommunications and network infrastructure, fiber optic cable splice closures play a crucial role in ensuring seamless connectivity. These closures are essential components that enable the transmission of data at high speeds over long distances through optical fibers. By providing a secure and reliable connection, fiber optic cable splice closures unleash the potential of fiber optic technology, allowing for efficient data transfer and communication. With their ability to protect and organize fiber optic cables, these closures contribute to the overall reliability and performance of network infrastructure. As advancements continue to be made in fiber optic technology, the potential for even faster and more reliable connectivity is being realized.

Exploring Types and Features

Fiber optic cable closures come in various designs, each serving a specific purpose in network infrastructure. Two common types of closures are joint closures and splice closures.

Understanding Different Closure Designs

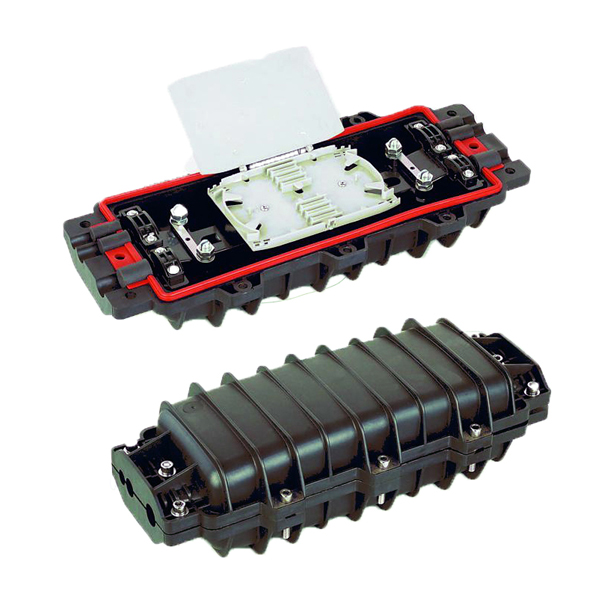

Joint closures are primarily used for connecting two or more fiber optic cables together. They provide a secure and reliable connection, ensuring efficient signal transmission between cables. Joint closures play a crucial role in expanding fiber optic networks by allowing seamless connections without compromising signal quality.

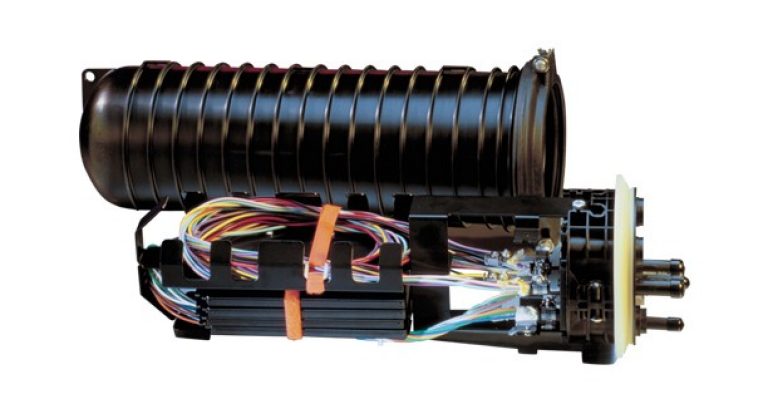

On the other hand, splice closures are designed to protect and organize spliced fiber optic cables. These closures offer robust protection against environmental factors such as moisture, dust, and temperature variations. By safeguarding the delicate spliced fibers, splice closures ensure the longevity and reliability of the fiber optic network.

Key Features and Benefits

Joint closures provide a secure connection that minimizes signal loss, enabling uninterrupted data transmission. They are essential for maintaining the integrity of fiber optic networks, especially in areas where multiple cables need to be connected.

Splice closures offer comprehensive protection for spliced fiber optic cables. Their key feature is their ability to shield the splices from external elements that could potentially degrade signal quality. By preventing moisture ingress, dust accumulation, and temperature fluctuations, splice closures ensure optimal performance and minimize downtime.

Both types of closures contribute to the overall efficiency of fiber optic networks by providing reliable connections and protecting critical components. Whether it's expanding an existing network or organizing spliced fibers, these closure designs play a vital role in maintaining the integrity and performance of modern telecommunications systems.

Factors Influencing Performance

The performance of fiber optic cable splice closures can be influenced by various factors, including environmental conditions and the quality of materials used.

Environmental Factors

Temperature fluctuations can have a significant impact on the performance of fiber optic cable splice closures. Extreme heat or cold can cause expansion or contraction, potentially affecting the integrity of the closure and leading to signal loss. It is crucial to consider temperature variations during installation and choose closures that are designed to withstand these conditions.

Humidity and moisture levels also play a critical role in maintaining optimal performance. Excessive moisture can lead to corrosion, which can degrade the signal quality over time. Proper sealing techniques and regular inspections are necessary to prevent moisture ingress and ensure long-term reliability.

In addition to temperature and humidity, proper installation techniques and cable management practices are essential for optimal performance. Cables should be carefully handled during installation to avoid stress or damage that could impact signal transmission. Adequate cable management within the closure helps maintain organization, reduces strain on the fibers, and minimizes the risk of accidental damage.

Quality of Materials

The quality of materials used in splice closures directly impacts their durability and longevity. High-quality closures are designed with robust sealing mechanisms that provide reliable protection against environmental factors. The strength of the closure housing is also crucial, as it ensures the physical integrity of the closure under various conditions.

Choosing splice closures from reputable manufacturers is essential for ensuring high performance and reliability. Reputable manufacturers adhere to strict quality standards, use superior materials, and conduct rigorous testing to guarantee optimal functionality. Investing in high-quality closures not only enhances performance but also reduces maintenance requirements and potential downtime.

By considering environmental factors such as temperature, humidity, proper installation techniques, cable management practices, as well as selecting high-quality materials from reputable manufacturers, professionals can ensure optimal performance from their fiber optic splice closures.

Case Studies: Successful Implementations

Real-world case studies demonstrate the effectiveness of fiber optic splice closures in improving connectivity and enhancing network infrastructure. Let's explore two successful implementations:

Case Study 1: Fiber Optic Network Expansion

A telecommunications company embarked on a fiber optic network expansion project, aiming to meet the growing demand for high-speed communication networks. They utilized advanced splice closures to ensure reliable protection and easy access for maintenance and repairs. The closures played a crucial role in safeguarding the spliced fiber optic cables from environmental factors, ensuring uninterrupted signal transmission. As a result of this network expansion, the telecommunications company experienced improved connectivity, enabling faster data transfer and enhanced customer satisfaction.

Case Study 2: Data Center Upgrade

A data center recognized the need to upgrade its infrastructure to accommodate increasing data demands. They opted for high-performance splice closures to ensure uninterrupted data transmission and minimize downtime during the upgrade process. These closures provided robust protection for the spliced fibers, safeguarding them from external elements that could potentially disrupt signal quality. The upgrade not only enhanced the data center's capacity but also improved overall efficiency by reducing potential interruptions and maintaining seamless connectivity.

These case studies highlight how implementing advanced splice closures can have a significant impact on telecom networks and data centers. By leveraging these technologies, organizations in the telecom industry can enhance their communication networks, improve reliability, and meet the ever-growing demands of modern-day connectivity.

Future Trends in Splice Closures

As technology continues to advance, the future of splice closures holds exciting possibilities for network infrastructure and telecom industry.

Advancements in Closure Design

New closure designs are being developed to accommodate higher fiber counts. With the increasing demand for faster and more reliable network connectivity, these advanced closures can handle larger volumes of data transmission, supporting the growth of communication infrastructure.

In addition to accommodating higher fiber counts, smaller and more compact closures are being introduced. These space-constrained installations require closures that can fit into tight spaces without compromising performance. The development of smaller closures enables efficient utilization of available real estate while maintaining optimal network connectivity.

To improve closure performance, advanced sealing techniques are being implemented. These techniques enhance the closure's ability to withstand environmental factors such as moisture, dust, and temperature variations. By ensuring a robust seal, these advancements contribute to the longevity and reliability of the telecom infrastructure.

Integration of Smart Technologies

The integration of smart features into splice closures is another significant trend on the horizon. Splice closures equipped with remote monitoring and management capabilities enable real-time status updates and predictive maintenance. This integration with IoT technologies allows for proactive identification of potential issues, reducing downtime and optimizing network efficiency.

Smart closures also contribute to cost reduction by streamlining operations. With remote monitoring capabilities, technicians can efficiently manage multiple closures from a centralized location, minimizing the need for physical inspections and on-site visits. This not only saves time but also reduces operational costs associated with maintenance and repairs.

By embracing these future trends in splice closures, network infrastructure professionals can stay ahead in an ever-evolving industry. The advancements in closure design and integration of smart technologies will pave the way for improved telecom infrastructure, enhanced network connectivity, and efficient communication systems.

Embracing the Advancements

The future of fiber optic cable splice closures is filled with exciting innovations and advancements. As professionals in the telecommunications industry, it is crucial to understand the different closure types, consider performance factors, and learn from successful implementations. By staying updated with the latest technologies and embracing future trends, we can ensure seamless connectivity and improved network infrastructure. The continuous evolution of fiber optic technology opens up new possibilities for faster data transmission, enhanced reliability, and efficient communication systems. By embracing these advancements, we can unlock the full potential of fiber optic technology and create a more connected world.

See Also

The Future of Fiber Optic Splice Closures: Exploring the 24 Core Configuration

The Future of Fiber Optic Connectors: Trends and Advancements

Exploring the Pros and Cons of PLC Blockless Splitters in Fiber Optic Networks

About US

Follow Us

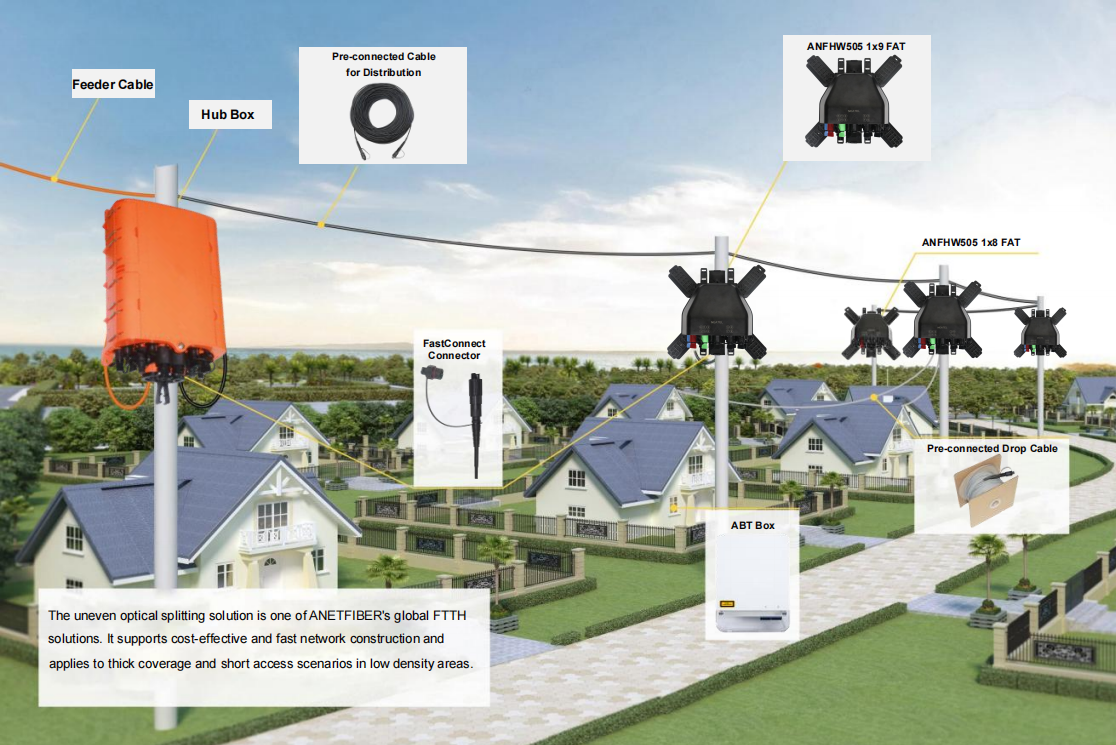

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586