The Future of Outdoor Fiber Patch Cables: Exploring the Advantages of Preconnection Solutions

The Future of Outdoor Fiber Patch Cables

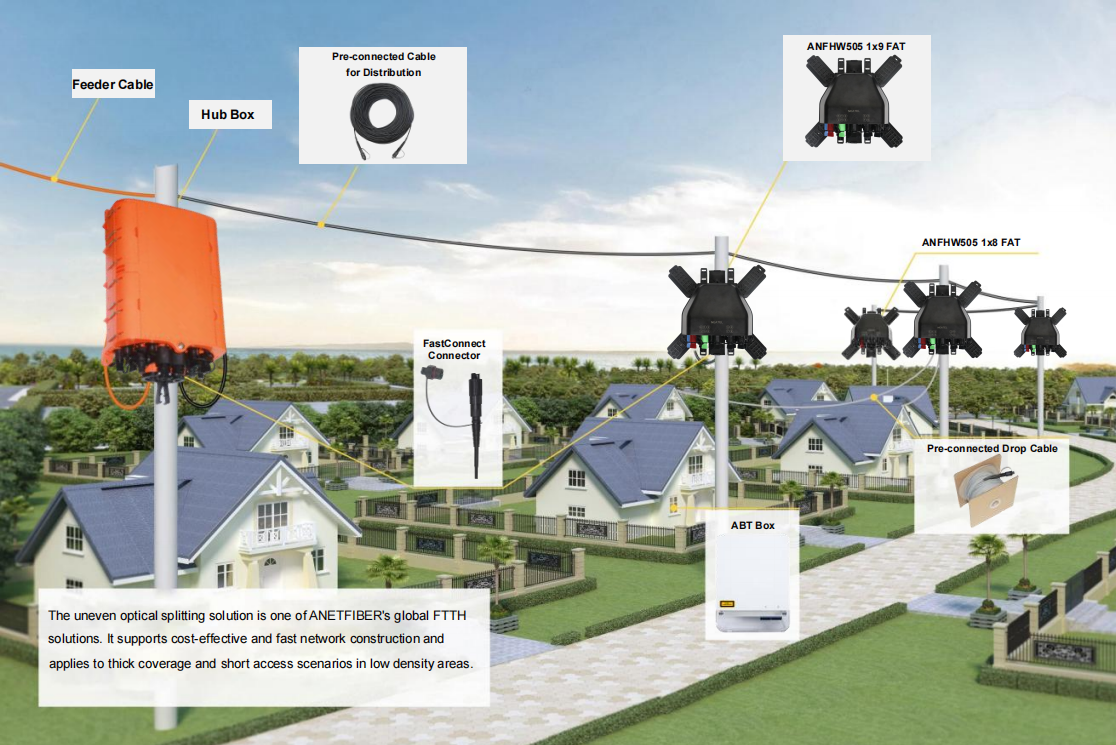

Outdoor fiber patch cables play a crucial role in ensuring reliable and high-performance connectivity in various industries. As technology continues to advance, the future of outdoor fiber patch cables looks promising with the emergence of preconnection solutions. These innovative solutions offer numerous advantages, including reduced installation time and cost, improved reliability, and enhanced performance.

Preconnection solutions involve preterminated or preconnected fiber cables that are ready for immediate use. By eliminating the need for field terminations, these solutions simplify the installation process and minimize the risk of errors. They also reduce maintenance requirements, as preconnected cables are less prone to damage or signal loss.

The use of preconnection solutions in outdoor fiber patch cables is gaining popularity due to their efficiency and convenience. Network administrators, IT professionals, and telecommunications engineers can benefit from these advancements by ensuring reliable connectivity in challenging outdoor environments.

Exploring the Advantages of Preconnection Solutions

Preconnection solutions offer a range of benefits that make them an attractive choice for outdoor fiber patch cables. Let's delve into the advantages they provide:

Benefits of Preconnection Solutions

Reduced installation time and cost: With preconnected solutions, the need for field terminations is eliminated, saving valuable time and labor costs. The cables come preterminated with connectors, ready to be deployed immediately.

Improved reliability and performance: Preconnected fiber cables undergo rigorous testing and quality control measures before being shipped. This ensures that they meet industry standards and deliver consistent performance, minimizing the risk of signal loss or degradation.

Applications of Preconnection Solutions

Preconnection solutions find applications in various outdoor environments with harsh conditions, where traditional fiber cables may be susceptible to damage. These include:

Outdoor installations in industries such as oil and gas, mining, transportation, and manufacturing, where exposure to extreme temperatures, moisture, dust, or chemicals is common.

Telecommunications networks and data centers that require reliable connectivity in demanding environments.

By utilizing preconnection solutions in these applications, network administrators can ensure robust and weather-resistant connections that withstand challenging conditions.

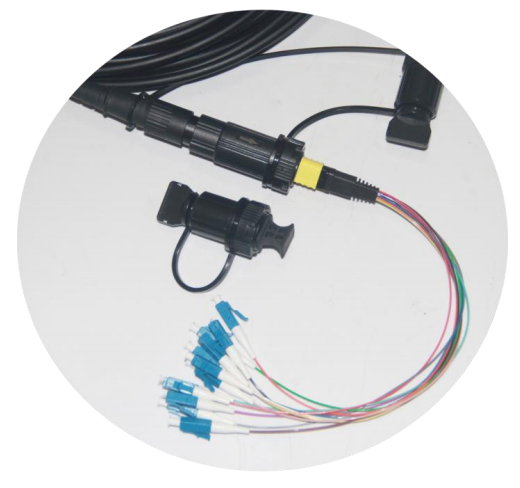

The IP67 LC Duplex Singlemode Waterproof TPU Armored Outdoor Fiber Patch Cable

The IP67 LC Duplex Singlemode Waterproof TPU Armored Outdoor Fiber Patch Cable is a cutting-edge solution designed to withstand the challenges of outdoor environments. Let's explore its features, specifications, and the benefits it offers:

Features and Specifications

IP67 rating for protection against dust and water: The IP67 rating ensures that the cable is completely dustproof and can withstand immersion in up to 1 meter of water for a limited time. This makes it ideal for outdoor installations where exposure to moisture or environmental contaminants is a concern.

LC Duplex connectors for high-density applications: The LC Duplex connectors provide a compact and high-density solution, making them suitable for applications that require multiple connections in limited space.

TPU armored for enhanced durability: The cable is reinforced with a thermoplastic polyurethane (TPU) armor, which provides excellent resistance against abrasion, impact, and bending. This protective TPU coating ensures the longevity of the cable in harsh outdoor conditions.

Use Cases and Benefits

The IP67 LC Duplex Singlemode Waterproof TPU Armored Outdoor Fiber Patch Cable finds extensive use in various industries and offers several benefits:

Ideal for outdoor installations in various industries: Its rugged construction makes it well-suited for outdoor deployments in industries such as oil and gas, transportation, mining, and manufacturing. It can withstand extreme temperatures, moisture, chemicals, and other challenging environmental conditions.

Ensures reliable and uninterrupted connectivity: With its waterproof design and durable TPU armor, this fiber patch cable provides reliable connectivity even in harsh outdoor environments. It minimizes signal loss or interruption due to external factors like moisture or physical damage.

By utilizing the IP67 LC Duplex Singlemode Waterproof TPU Armored Outdoor Fiber Patch Cable, network administrators can ensure robust connectivity that meets their requirements while withstanding the rigors of outdoor installations.

Comparing Preconnection Solutions with Traditional Fiber Patch Cables

When it comes to outdoor fiber patch cables, preconnection solutions offer several advantages over traditional fiber patch cables. Let's compare the two in terms of installation, maintenance, reliability, and performance:

Installation and Maintenance

Simplified installation process with preconnected solutions: Preconnected fiber cables come ready for immediate use, eliminating the need for field terminations. This simplifies the installation process and reduces the risk of errors during termination. On the other hand, traditional fiber patch cables require time-consuming field terminations, which can be complex and prone to mistakes.

Reduced maintenance requirements: Preconnected solutions are factory-tested and quality-controlled before shipment, ensuring their reliability. As a result, they have lower maintenance requirements compared to traditional fiber patch cables. Non-preconnected fiber cables may require periodic inspections and reterminations to maintain optimal performance.

Reliability and Performance

Higher reliability and lower signal loss with preconnected solutions: Preconnection solutions undergo rigorous testing to ensure their performance meets industry standards. The factory-terminated connectors provide consistent and reliable connectivity with minimal signal loss or degradation. In contrast, traditional fiber patch cables may be more susceptible to signal loss due to imperfect field terminations.

Improved performance in challenging environments: Preconnected solutions often come with additional features like waterproof or armored protection that enhance their durability in harsh outdoor environments. This makes them more resilient against moisture, dust, temperature variations, and physical damage compared to conventional fiber patch cables.

By opting for preconnection solutions over traditional fiber patch cables, network administrators can enjoy simplified installations, reduced maintenance efforts, higher reliability, and improved performance in challenging outdoor conditions.

Future Trends and Advancements in Outdoor Fiber Patch Cable Technology

As technology continues to evolve, the future of outdoor fiber patch cables holds exciting possibilities. Let's explore some of the emerging trends and advancements in this field:

Emerging Technologies

Advancements in fiber optic connectors and termination methods: Ongoing research and development are leading to improved fiber optic connectors that offer higher performance, increased durability, and easier installation. New termination methods are also being developed to enhance efficiency and reliability.

Innovations in cable design for increased durability and performance: Manufacturers are constantly working on developing new cable designs that can withstand harsh outdoor conditions while delivering optimal performance. These innovations include enhanced protection against moisture, dust, temperature variations, and physical damage.

Growing Demand and Applications

Increasing need for high-speed and reliable outdoor connectivity: With the growing demand for high-speed internet access and reliable connectivity in outdoor environments, there is a rising need for advanced outdoor fiber patch cables. These cables will be capable of supporting higher bandwidths, ensuring seamless communication in applications such as video surveillance, smart city infrastructure, and outdoor Wi-Fi networks.

Expanding applications in smart cities, IoT, and 5G networks: As smart cities continue to develop and IoT devices become more prevalent, the demand for outdoor fiber patch cables will increase. These cables will play a crucial role in providing reliable connectivity for various IoT sensors, devices, and infrastructure. Additionally, with the advent of 5G networks, there will be a need for robust outdoor fiber patch cables to support the increased data speeds and network capacity.

The future of outdoor fiber patch cable technology looks promising with upcoming developments aimed at improving performance, durability, and meeting the evolving demands of high-speed connectivity in outdoor environments.

The Significance of Preconnection Solutions

Preconnection solutions play a significant role in the world of outdoor fiber patch cables. They offer numerous benefits that contribute to reliable and efficient connectivity in challenging environments. By utilizing preconnected or preterminated fiber cables, network administrators can save time and costs associated with field terminations, while also ensuring higher reliability and performance.

These solutions are particularly crucial for outdoor installations where exposure to harsh conditions like moisture, dust, and extreme temperatures is common. The use of preconnection solutions minimizes the risk of errors during installation and reduces maintenance requirements, resulting in improved overall efficiency.

As technology continues to advance, future advancements in outdoor fiber cable technology will further enhance the performance and durability of preconnection solutions. Network administrators can look forward to more innovative designs and features that meet the growing demand for high-speed and reliable connectivity in outdoor environments.

See Also

The Future of Preconnection Solutions: Exploring Features, Applications, and Technology

Exploring the Benefits of Fiber Solutions for Structured Cabling

MU Fiber Optic Pigtails: Key Features and Benefits for Network Engineers

Understanding Different Types of Fiber Optic Adapters: A Comprehensive Guide

Choosing the Best Fiber Optic Splitters: The ABS PLC Advantage

About US

Follow Us

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586