The Future of Fiber Optic Closures: Innovations for Harsh Conditions

Unveiling Innovations in Fiber Optic Closures

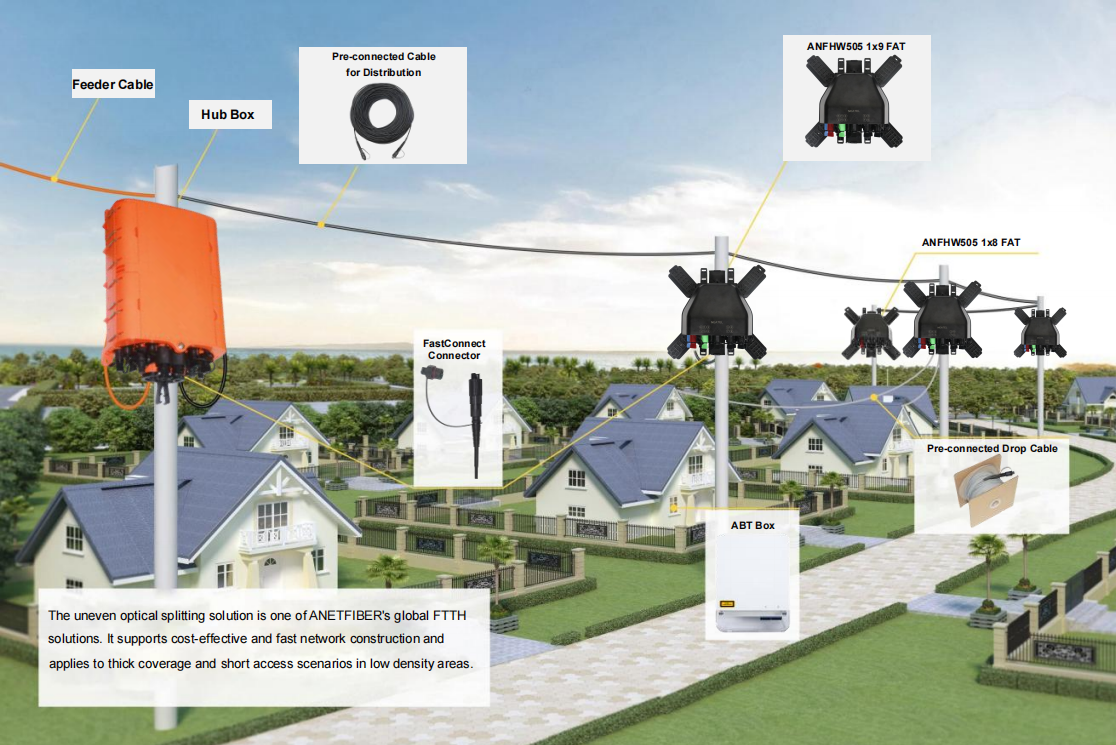

In the ever-evolving world of telecommunications, fiber optic closures play a crucial role in ensuring reliable connectivity, even in the harshest of conditions. These closures are designed to protect and secure the delicate fiber optic cables that transmit data over long distances. By providing a robust barrier against external elements, such as extreme temperatures, moisture, and physical damage, fiber optic closures ensure uninterrupted communication. As technology advances, innovations in closure design and materials continue to enhance their performance. These advancements focus on improving durability and ease of installation while maintaining optimal signal transmission. The future of fiber optic closures holds great promise for the telecommunications industry, offering improved reliability and connectivity for networks worldwide.

Ensuring Reliable Connectivity in Extreme Environments

Importance of Fiber Optic Closures in Extreme Environments

Fiber optic closures play a vital role in ensuring reliable connectivity in extreme environments. These closures act as protective enclosures for fiber optic termination boxes, safeguarding the delicate fiber optic cables from harsh conditions. In extreme temperatures, such as scorching heat or freezing cold, fiber optic closures provide insulation and prevent damage to the cables. They also offer resistance against moisture, preventing water ingress that could disrupt signal transmission. Additionally, fiber optic closures protect against physical damage caused by impact or vibration, ensuring uninterrupted communication even in challenging environments.

Benefits of Fiber Optic Closures in Challenging Conditions

Fiber optic closures offer numerous benefits when it comes to maintaining connectivity in challenging conditions. One of the key advantages is enhanced durability. Designed to withstand extreme temperatures and harsh weather conditions, these closures ensure the longevity of the fiber optic network. They are also resistant to moisture and can effectively seal out water, preventing corrosion and signal degradation. Furthermore, fiber optic closures provide protection against physical damage from external factors like impact or vandalism.

By utilizing fiber optic closures in challenging environments, telecommunication networks can maintain reliable connectivity without compromising on performance or data integrity.

Exploring Versatile Solutions for Challenging Conditions

Types of Fiber Optic Closures Suitable for Harsh Environments

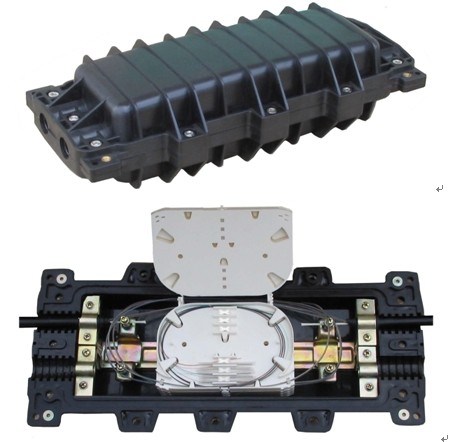

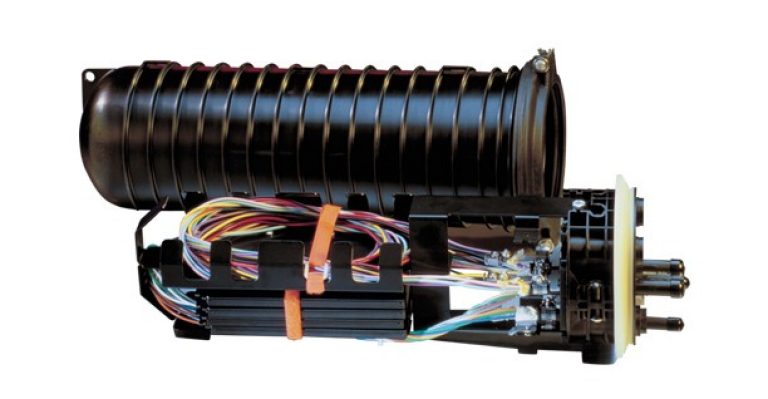

When it comes to challenging conditions, there are various types of fiber optic closures available, each designed to meet specific requirements. One common type is dome closures, which provide a protective enclosure for fiber optic termination boxes. Dome closures are known for their versatility and can be used in a wide range of harsh environments. Another option is inline closures, which are compact and ideal for installations where space is limited. These closures offer excellent protection against extreme temperatures and physical damage.

Heat shrink closures are another popular choice for harsh environments. They use heat shrinkable tubing to seal the fiber optic cables, providing reliable protection against moisture and other environmental factors. These closures are particularly effective in areas prone to high humidity or water ingress.

Key Considerations for Selecting the Right Closure

When selecting a fiber optic closure for challenging conditions, several key considerations should be taken into account. First and foremost, the environmental conditions must be assessed. Factors such as temperature variations, exposure to moisture or chemicals, and the presence of dust or debris can impact the choice of closure.

The cable capacity required is another important consideration. Different closures have varying capacities to accommodate different numbers of fiber optic cables. It's essential to choose a closure that can handle the anticipated cable load without compromising performance or future scalability.

Lastly, installation requirements should be considered. Some closures may require specialized tools or techniques for installation, while others offer more straightforward installation processes. Evaluating these requirements ensures that the selected closure can be installed efficiently and effectively.

By carefully considering these factors, telecommunication professionals can select the right fiber optic closure that meets their specific needs in challenging conditions.

Future Trends and Advancements in Closure Technology

Innovations Shaping the Future of Fiber Optic Closures

The future of fiber optic closures is driven by continuous advancements in closure technology. These innovations are focused on improving durability, ease of installation, and scalability. One key area of development is the introduction of modular designs. Modular closures allow for easier customization and expansion as network requirements evolve. They offer flexibility in accommodating different cable capacities and can be easily upgraded or modified without disrupting the entire network.

Another significant advancement is the integration of advanced sealing mechanisms. These mechanisms provide enhanced protection against water ingress, dust, and other environmental factors that can compromise signal transmission. By implementing improved sealing techniques, fiber optic closures can ensure long-term reliability even in the harshest conditions.

Additionally, closure technology is evolving to simplify installation processes. Manufacturers are developing closure solutions that require minimal tools and expertise for installation. This not only saves time but also reduces the risk of errors during deployment.

As enclosure technology continues to advance, it holds great promise for the telecommunications industry by providing more efficient and reliable connectivity solutions for challenging environments.

Best Practices for Maintaining Closures in Harsh Environments

To ensure the longevity and optimal performance of fiber optic closures in harsh environments, proper maintenance practices are essential. Regular inspection should be conducted to identify any signs of damage or degradation. Cleaning procedures should also be implemented to remove dust or debris that may accumulate over time.

Preventive maintenance measures play a crucial role in protecting closures from environmental hazards. Proper sealing techniques should be employed to prevent water ingress, which can lead to corrosion or signal loss. Physical protection measures such as using protective enclosures or implementing security protocols can safeguard closures against vandalism or accidental damage.

By following these best practices, telecommunication professionals can maximize the lifespan and reliability of fiber optic closures in challenging environments.

Embracing the Superiority of Fiber Optic Closures

Fiber optic closures have emerged as the superior choice for ensuring reliable connectivity in harsh conditions. Their versatility, durability, and advancements in technology make them the future of telecommunications infrastructure. Unlike traditional alternatives, fiber optic closures provide a robust protective enclosure for fiber optic termination boxes, safeguarding delicate cables from extreme temperatures, moisture, and physical damage. With their ability to withstand challenging environments, these closures offer uninterrupted communication and enhanced network performance. As telecommunication professionals embrace the superiority of fiber optic closures, they can confidently build resilient networks that meet the demands of today's ever-evolving world.

See Also

The Future of Fiber Optic Cable Splice Closures: Trends and Innovations

The Future of Fiber Optic Splice Closures: Exploring the 24 Core Configuration

The Future of Fiber Optic Connectors: Trends and Advancements

The Future of Fiber Optic Networks: Exploring FC to LC Adapters

The Future of Fiber Optic: Exploring the Benefits of 24 Fiber MPO Cables

About US

Follow Us

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586