How to Efficiently Install Fiber Optic Fast Connectors

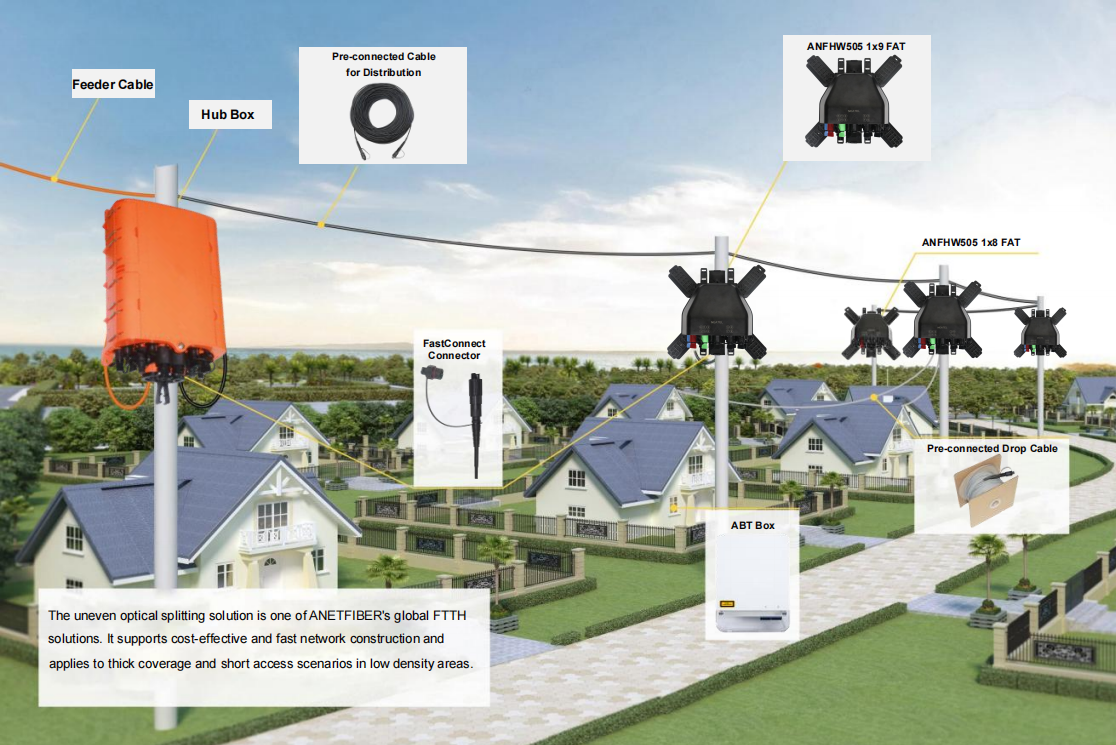

Efficient installation of fiber optic fast connectors ensures optimal performance and reliability. Fiber optic fast connectors, such as MINISC and AFL Fast SC Connector, provide quick and secure connections for various applications. These connectors enhance FiberInstallation by reducing setup time and minimizing errors. The use of FastConnector in FTTH (Fiber to the Home) networks improves data transmission efficiency. Additionally, these connectors offer cost-effectiveness and ease of use, making them ideal for high-density environments like data centers and enterprise networks. The hardenadapter feature in these connectors ensures a robust connection, while the preconnect capability simplifies the installation process. Moreover, the fiberdropcable compatibility further enhances their versatility in various fiber optic installations.

Preparation

Tools and Materials Needed

List of essential tools

Efficient installation of FiberOptic fast connectors requires specific tools. Installers need a fusion splicer for concatenation of long cable runs and splicing on pigtails. Termination equipment for multimode fiber is essential. Preferred methods include adhesive/polish or prepolished/splice types. Various termination kits and consumables like wipes, isopropyl alcohol, and cable gel cleaner are necessary. Safety equipment such as safety glasses and black work mats are crucial for FiberOptic work.

List of required materials

Installers must have the right materials to ensure successful installation. Essential materials include fiber optic cables, fast connectors, and fiberdropcable. Additional materials such as connector boots, splice sleeves, and cleaning supplies are also necessary. Having all these materials ready will streamline the installation process and reduce downtime.

Safety Precautions

Personal protective equipment

Safety is paramount when working with FiberOptic cables. Installers must wear safety glasses to protect their eyes from fiber shards. Black work mats help in identifying small fiber pieces that may pose a hazard. Gloves can protect hands from cuts and abrasions. Ensuring the use of proper personal protective equipment will minimize the risk of injury.

Handling fiber optic cables

Proper handling of FiberOptic cables is crucial for maintaining their integrity. Avoid bending the cables sharply to prevent damage to the fibers inside. Use cable pullers or plows for laying cables to avoid unnecessary strain. Clean the cables with isopropyl alcohol before making any connections. Proper handling ensures the longevity and performance of the fiberdropcable and other fiber optic components.

Step-by-Step Installation Guide

Step 1: Cable Preparation

Stripping the cable

Begin by stripping the outer jacket of the fiber optic cable. Use a precision stripper to remove approximately 50mm of the jacket. Ensure a clean cut to avoid damaging the internal fibers. Proper stripping prepares the cable for the next steps in the FiberInstallation process.

Cleaning the fiber

Clean the exposed fiber using isopropyl alcohol and lint-free wipes. Remove any debris or residue that could interfere with the connection. Clean fibers ensure optimal performance and reduce the risk of signal loss.

Step 2: Connector Preparation

Inspecting the connector

Inspect the FastConnector for any defects or contaminants. Check the ferrule and alignment sleeve for cleanliness. A thorough inspection guarantees a reliable connection during FiberInstallation.

Preparing the connector for installation

Prepare the FastConnector by opening the latch mechanism. Align the internal components to facilitate easy insertion of the fiber. Proper preparation ensures a seamless preconnect process.

Step 3: Connecting the Fiber

Inserting the fiber into the connector

Insert the cleaned fiber into the prepared FastConnector. Ensure the fiber aligns correctly with the internal components. A slight bend in the fiber helps guide it into place. Proper insertion is crucial for a successful FiberInstallation.

Securing the connection

Secure the connection by closing the latch mechanism on the FastConnector. Apply gentle pressure to lock the fiber in place. A secure connection ensures optimal performance and longevity.

Step 4: Testing the Connection

Using a Visual Fault Locator

A visual fault locator (VFL) helps identify any issues in the fiber optic connection. Activate the VFL by turning on the laser light. Insert the VFL into the connector. Observe the fiber for any visible light leaks. Light leaks indicate breaks or bends in the fiber. Address these issues immediately to ensure a robust connection.

Verifying Signal Strength

Signal strength verification ensures optimal performance of the fiber optic connection. Use an optical power meter for this task. Connect the optical power meter to the fiber optic cable. Measure the signal strength transmitted through the fiber. Compare the measured value with the expected range. A strong signal indicates a successful installation. Weak signals require re-evaluation of the connection. Verify all connections in FTTH networks to maintain high data transmission efficiency.

Common Pitfalls and Tips

Avoiding Common Mistakes

Incorrect cable stripping

Incorrect cable stripping can lead to damaged fibers and poor connections. Installers must use a precision stripper to remove the outer jacket without nicking the internal fibers. Always measure and strip approximately 50mm of the jacket for optimal results. Proper stripping ensures the integrity of the fiber and prepares it for further steps.

Poor cleaning of the fiber

Poor cleaning of the fiber can result in signal loss and connection issues. Use isopropyl alcohol and lint-free wipes to clean the exposed fiber thoroughly. Any debris or residue on the fiber can interfere with the connection. Clean fibers guarantee optimal performance and reduce the risk of connection failures.

Additional Tips for Success

Ensuring proper alignment

Proper alignment of the fiber within the connector is crucial for a successful installation. Align the fiber correctly with the internal components of the FastConnector. A slight bend in the fiber helps guide it into place. Ensuring proper alignment prevents signal loss and enhances the overall performance of the connection.

Regular maintenance and checks

Regular maintenance and checks are essential for maintaining the integrity of fiber optic connections. Periodically inspect connectors for any signs of wear or contamination. Use a visual fault locator (VFL) to identify any issues in the fiber optic connection. Regular checks ensure that the connections remain robust and efficient over time.

Efficient installation of fiber optic fast connectors requires careful attention to detail. Each step in the process ensures optimal performance and reliability. Following the guidelines guarantees a secure and effective connection. Practicing these techniques will refine skills and enhance proficiency. Mastery of these steps will lead to successful installations and improved data transmission efficiency.

See Also

What Are the Components of Fiber and 5G?

Understanding the Differences Between FBT and PLC Splitters

How to Choose Reliable Fiber Splice Closures

MPO Cable Assemblies for Modern Data Centers

What Are Distribution Boxes and Their Functions in Fiber Optics

About US

Follow Us

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586