Comparing the Advantages of FRP and Steel for ADSS Cable: A Comprehensive Guide

Understanding ADSS Cable

Importance of ADSS Cable in Telecommunications

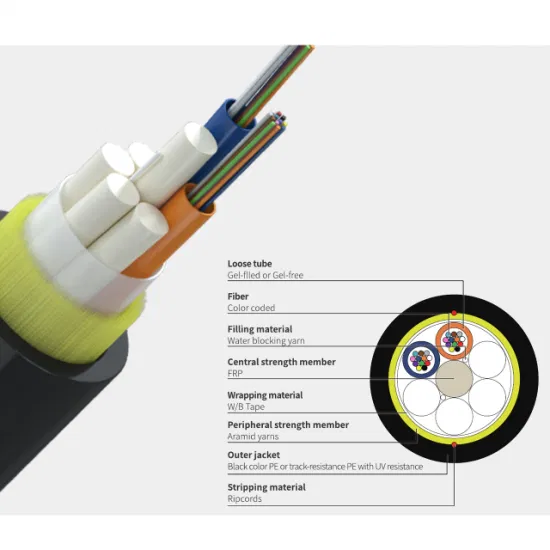

ADSS cable, also known as all-dielectric self-supporting cable, plays a critical role in telecommunications infrastructure. It serves as a reliable medium for transmitting data through fiber optic cables. The selection of materials for ADSS cable is paramount to ensure its optimal performance and longevity. Whether choosing between FRP or steel materials, the decision significantly impacts the overall effectiveness and durability of the ADSS wire.

Benefits of ADSS Cable

Reliability and Durability

ADSS cable is designed to provide high reliability and durability, making it a dependable choice for various environmental conditions. Its all-dielectric self-supporting structure ensures that it can withstand the challenges posed by different climates and terrains. The fiber optic cable within the ADSS wire is well-protected, contributing to its long-term performance. Additionally, the cable is resistant to corrosion, further enhancing its durability over time.

Cost-Effectiveness

The cost-effectiveness of ADSS cable stems from its self-supporting nature, which reduces installation and maintenance expenses. Unlike traditional cables, ADSS cable does not require additional support structures such as messenger wires or lashing. This eliminates the need for extra hardware and labor, resulting in significant cost savings. Moreover, its self-supporting design streamlines the installation process, making it an efficient and economical solution for telecommunications infrastructure.

By incorporating ADSS cable into telecommunications networks, organizations can benefit from its reliability, durability, and cost-effectiveness while ensuring seamless data transmission capabilities.

Properties of FRP

Lightweight and Non-Conductive

When considering materials for ADSS cable, FRP stands out due to its lightweight nature. The use of fiber reinforced polymer (FRP) or fiberglass reinforced plastic (FRP) in the construction of ADSS cable makes it easy to handle during installation. This lightweight characteristic streamlines the installation process, reducing the time and labor required for setup. Additionally, FRP materials are non-conductive, minimizing the risk of electrical hazards during handling and deployment.

High Tensile Strength

One of the key advantages of composite materials like FRP is their high tensile strength. This attribute ensures that the ADSS cable receives robust support from the FRP components. The high tensile strength of FRP enables it to withstand environmental stresses effectively, contributing to the overall durability and longevity of the ADSS cable infrastructure.

Strength of Steel

Exceptional Load-Bearing Capacity

Steel is renowned for its exceptional load-bearing capacity, making it an ideal choice for ADSS cable installations. The inherent strength of steel materials allows them to support the weight and tension of the cable effectively. This high load-bearing capacity ensures stability and reliability in various environmental conditions, contributing to the overall robustness of the telecommunications infrastructure.

Resilience to Environmental Factors

Steel materials exhibit remarkable resilience to environmental factors such as wind and ice loading, making them suitable for demanding applications. Their ability to withstand harsh weather conditions ensures that the ADSS cable remains secure and functional even in challenging environments. This resilience is a key factor in maintaining uninterrupted data transmission capabilities, especially in areas prone to extreme weather events.

Steel offers exceptional load-bearing capacity

Its resilience to environmental factors ensures reliability

The high-strength material provides stability for ADSS cable installations

ADSS Cable Installation

Installation Techniques

Proper installation techniques play a crucial role in maximizing the performance and longevity of ADSS cable. During installation, factors such as tensioning, sag, and clearance must be meticulously considered to ensure the cable's optimal functionality. Adequate tensioning is essential to maintain the structural integrity of the cable and prevent excessive stress on the fiber optic components. Additionally, managing sag effectively contributes to minimizing strain on the cable and supports its ability to withstand environmental challenges. Furthermore, maintaining appropriate clearance from surrounding objects or structures is vital to prevent any physical damage to the all-dielectric self-supporting cable during its operational lifespan.

List:

Adequate tensioning is crucial for maintaining structural integrity

Managing sag effectively minimizes strain on the cable

Maintaining appropriate clearance prevents physical damage

Multifiber Optic Cable Applications

ADSS cable is well-suited for supporting multifiber optic cable applications, offering high bandwidth capabilities for efficient data transmission in telecommunications networks. The robust design of ADSS wire ensures that it can accommodate multiple fiber optic cables without compromising its self-supporting nature. This makes it an ideal choice for applications requiring seamless and reliable data transmission over long distances.

By incorporating proper installation techniques and leveraging its support for multifiber optic cable applications, ADSS cable proves to be a versatile solution for telecommunications infrastructure.

Choosing the Right Material for ADSS Cable

Material Selection Considerations

When deciding between FRP and steel for ADSS cable installations, several factors should be taken into account. Firstly, the specific environmental conditions in which the cable will be deployed play a crucial role. For instance, areas prone to extreme weather may benefit from the resilience of steel, while FRP's non-conductive nature could be advantageous in certain settings. Secondly, the load-bearing requirements and installation constraints must be carefully evaluated to determine the most suitable material for ensuring the longevity and reliability of the all-dielectric self-supporting cable.

Environmental conditions

Load-bearing requirements

Installation constraints

Comparative Analysis

Conducting a comparative analysis of the benefits offered by both FRP and steel materials is essential. By examining factors such as weight, tensile strength, and resistance to environmental stresses, organizations can make informed decisions about which material aligns best with their specific ADSS cable needs.

Conclusion

By thoroughly evaluating the advantages of FRP and steel materials in relation to the unique demands of ADSS cable, organizations can make well-informed choices regarding material selection. This comprehensive approach ensures that telecommunications infrastructure is equipped with the most suitable material for achieving reliable and efficient data transmission capabilities.

See Also

Exploring LC Series Fiber Optic Breakout Cables and Duplex Multi-Mode Fiber Solutions

LC Series Fiber Adapter Panels: OS2 Single Mode vs. OM4 Multimode Solutions

Maximizing Data Center Efficiency with MPO Trunk Cable Solutions

2024 Trends: Exploring MPO Branch Cable in Data Center Solutions

Maximizing Data Center Efficiency with MPO Series Trunk Cables

About US

Follow Us

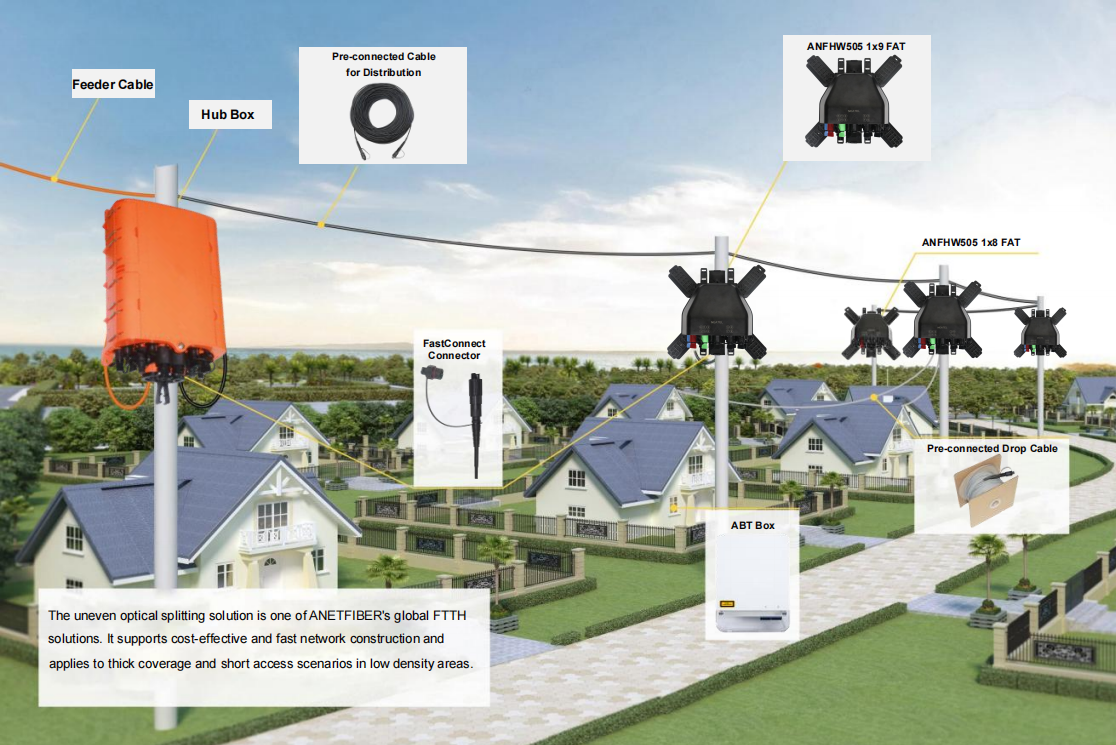

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586