Choosing the Right Fiber Splice Enclosure for Outdoor Installations

Choosing the appropriate fiber optic splice closure is essential for outdoor installations, where environmental factors like weather conditions and physical stress can be challenging. A well-selected splicebox is vital for ensuring reliable protection of optical signals. The fusionfiber process demands a sturdy jointbox to preserve signal integrity. Proper selection of a cablesplicer requires an understanding of the specific needs of the installation site. This guidance aims to offer insights into making informed decisions for optimal performance in splicingfiber applications.

Understanding Fiber Splice Enclosures

Definition and Purpose

What is a Fiber Splice Enclosure?

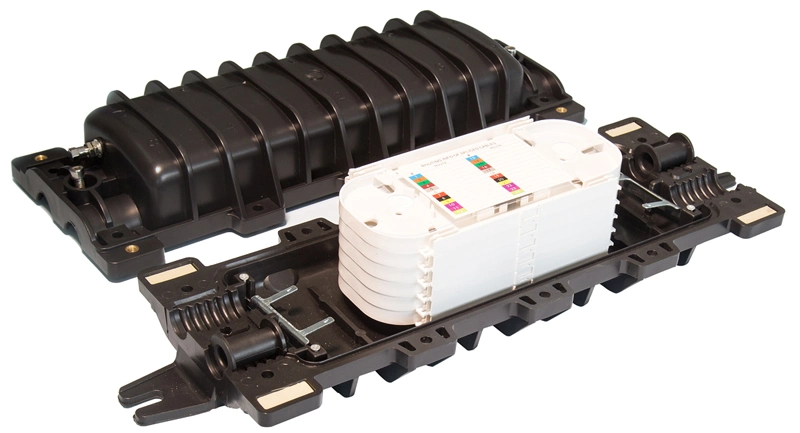

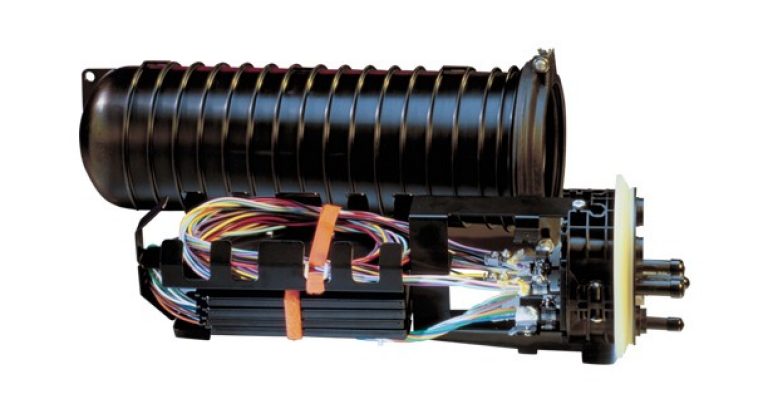

A fiber splice enclosure serves as a protective housing for joining fiber optic cables. The primary function of this splicebox is to safeguard the delicate opticalsignal connections from environmental hazards. The fiberopticspliceclosure accommodates various numbers of cables, fibers, and splices. This structure ensures that each cablesplicer remains organized and secure. The design of the jointbox provides essential protection against physical damage and environmental factors.

Why are they essential for outdoor installations?

Outdoor installations demand robust protection due to exposure to harsh conditions. A fiberopticspliceclosure shields the fusionfiber process from moisture, dust, and temperature fluctuations. The splicebox plays a critical role in maintaining the integrity of opticalsignal transmissions. Without proper protection, the cablesplicer may suffer from signal degradation or failure. The jointbox ensures long-term reliability and performance in outdoor environments.

Types of Fiber Splice Enclosures

Dome Enclosures

Dome enclosures offer versatile solutions for various installation scenarios. The design suits aerial, buried, or underground applications. The rounded shape of the splicebox provides excellent resistance against external pressures. The fiberopticspliceclosure in dome form allows for easy access during maintenance. The jointbox accommodates a significant number of splices, making it ideal for larger projects.

Inline Enclosures

Inline enclosures serve direct connection needs efficiently. The linear design of this splicebox facilitates straightforward installation along cable routes. The fiberopticspliceclosure offers streamlined protection for opticalsignal pathways. The jointbox ensures minimal disruption to existing infrastructure. This type of cablesplicer is suitable for installations requiring compact and efficient solutions.

Wall-Mount Enclosures

Wall-mount enclosures provide a practical option for fixed installations. The design allows for secure attachment to walls or other vertical surfaces. The splicebox offers organized space for splicing operations. The fiberopticspliceclosure ensures protection against environmental elements. The jointbox in wall-mount form supports easy access for maintenance and upgrades.

Key Considerations for Outdoor Installations

Environmental Factors

Weather Resistance

Weather resistance stands as a crucial factor for outdoor installations. A fiberopticspliceclosure must withstand harsh conditions like rain, snow, and wind. The splicebox should provide a secure environment to protect the opticalsignal from moisture intrusion. A robust jointbox ensures the longevity of the cablesplicer by preventing water damage. Selecting a fusionfiber enclosure with high weather resistance guarantees network reliability.

UV Protection

UV protection plays a vital role in maintaining the integrity of outdoor fiberopticspliceclosure systems. Prolonged exposure to sunlight can degrade materials and affect performance. A splicebox with UV-resistant properties shields the opticalsignal pathways from harmful rays. This protection extends the lifespan of the cablesplicer and maintains signal quality. A durable jointbox with UV protection is essential for outdoor installations.

Temperature Tolerance

Temperature fluctuations pose challenges for outdoor splicebox installations. A fiberopticspliceclosure must tolerate extreme heat and cold without compromising performance. The jointbox should maintain structural integrity across a wide temperature range. A cablesplicer designed for temperature tolerance ensures consistent opticalsignal transmission. Selecting a fusionfiber enclosure with appropriate temperature specifications enhances network stability.

Installation Requirements

Ease of Access

Ease of access simplifies maintenance and repairs for outdoor fiberopticspliceclosure systems. A well-designed splicebox allows technicians to reach the cablesplicer efficiently. The jointbox should provide clear pathways for managing opticalsignal connections. Easy access reduces downtime and improves serviceability. Choosing a fusionfiber enclosure with user-friendly features enhances operational efficiency.

Compatibility with Existing Infrastructure

Compatibility with existing infrastructure ensures seamless integration of new splicebox installations. A fiberopticspliceclosure must align with current systems to avoid disruptions. The jointbox should accommodate various cable types and sizes used in the network. A compatible cablesplicer facilitates smooth opticalsignal transitions. Selecting a fusionfiber enclosure that fits existing setups optimizes installation success.

Selecting the Right Enclosure

Material and Durability

Common Materials Used

Fiber splice enclosures come in various materials, each offering unique benefits. Polycarbonate and stainless steel are popular choices for their durability and resistance to environmental factors. Polycarbonate provides a lightweight option with excellent impact resistance. Stainless steel offers superior protection against corrosion and physical damage. Aluminum is another material often used due to its balance of strength and weight. Each material affects the overall performance of the fiberopticspliceclosure.

Assessing Durability Needs

Durability plays a crucial role in selecting the right splicebox for outdoor installations. The choice of material impacts the enclosure's ability to withstand harsh conditions. Polycarbonate suits environments with high impact risks. Stainless steel excels in areas prone to corrosion. Aluminum offers a middle ground for moderate conditions. Evaluating the specific needs of the installation site ensures the jointbox provides adequate protection for the opticalsignal.

Capacity and Scalability

Current and Future Needs

Capacity considerations are vital when choosing a cablesplicer. The splicebox must accommodate the current number of cables and splices. Future expansion plans should influence the decision as well. A fiberopticspliceclosure with sufficient space allows for easy upgrades. Planning for both present and future requirements ensures long-term efficiency.

Expansion Capabilities

Scalability determines the adaptability of a fusionfiber enclosure. An expandable jointbox supports network growth without needing complete replacement. Modular designs offer flexibility for adding more splices or cables. Choosing an enclosure with robust expansion capabilities enhances the overall performance of the splicingfiber system. This foresight reduces costs and effort in future upgrades.

Practical Tips and Best Practices

Installation Tips

Proper Sealing Techniques

Proper sealing techniques ensure the longevity of fiber splice enclosures. Technicians must apply seals to prevent moisture intrusion. Weatherproof gaskets provide a reliable barrier against environmental factors. Compression fittings enhance the enclosure's resistance to external pressures. A well-sealed enclosure maintains optimal performance in outdoor settings.

Cable Management

Effective cable management optimizes the functionality of fiber splice enclosures. Technicians should organize cables to prevent tangling. Labeling each cable aids in quick identification during maintenance. Secure fasteners keep cables in place and reduce strain. Proper cable routing minimizes signal loss and enhances system efficiency.

Maintenance and Inspection

Regular Inspection Protocols

Regular inspection protocols ensure the reliability of fiber splice enclosures. Scheduled checks identify potential issues before they escalate. Visual inspections detect signs of wear or damage. Testing equipment verifies the integrity of optical signals. Consistent maintenance extends the lifespan of the enclosure.

Troubleshooting Common Issues

Troubleshooting common issues resolves problems in fiber splice enclosures. Technicians should address signal loss promptly. Loose connections often cause disruptions in service. Moisture ingress requires immediate attention to prevent further damage. Accurate diagnostics lead to effective solutions and restore optimal performance.

FAQs and Comparisons

Common Questions

How to choose between dome and inline enclosures?

Choosing between dome and inline enclosures involves understanding specific installation needs. Dome enclosures offer versatility for aerial, buried, or underground applications. The rounded design of the splicebox provides excellent resistance against external pressures. Inline enclosures serve direct connection needs efficiently. The linear design facilitates straightforward installation along cable routes. Each cablesplicer type offers unique advantages depending on the project requirements. Evaluating the environmental conditions and space constraints helps in selecting the appropriate jointbox.

What are the cost considerations?

Cost considerations play a significant role in selecting a fiberopticspliceclosure. Material choice affects the overall expense. Polycarbonate enclosures provide a cost-effective option with good durability. Stainless steel options offer higher protection but come at a premium price. Installation complexity influences labor costs. A fusionfiber enclosure requiring minimal setup reduces expenses. Future scalability impacts long-term costs. An expandable splicebox may have a higher initial cost but saves money in future upgrades. Assessing these factors ensures a balanced investment in opticalsignal protection.

Comparing Different Brands

Brand A vs. Brand B

Brand A and Brand B offer distinct features in their fiberopticspliceclosure products. Brand A focuses on high-impact resistance with polycarbonate materials. The splicebox designs from Brand A provide easy access for maintenance. Brand B emphasizes corrosion resistance using stainless steel. The jointbox solutions from Brand B cater to harsh environments. Each brand offers unique benefits suited to different installation scenarios. Comparing these aspects assists in making an informed decision.

Features and Benefits

Features and benefits vary across fiberopticspliceclosure brands. Some brands offer modular designs for easy expansion. Others focus on compact splicebox solutions for limited spaces. UV protection and weather resistance remain standard features. Enhanced sealing techniques ensure optimal fusionfiber performance. Brands providing comprehensive warranties add value to the investment. Evaluating these features helps in selecting a cablesplicer that meets specific needs. Understanding the benefits ensures long-term reliability and efficiency in opticalsignal management.

Choosing the right fiber splice enclosure for outdoor installations requires careful consideration of several key factors. The selection process should focus on the specific requirements of the cable design and the environmental conditions. Informed decision-making ensures that the chosen enclosure will provide optimal protection and performance. Evaluating material durability, capacity needs, and installation requirements plays a crucial role. A comprehensive approach to selecting a splice closure guarantees long-term network reliability and efficiency. Each factor contributes to achieving the best possible outcome for fiber optic installations.

See Also

What Makes Fiber Optic Splice Closures Essential?

Choosing the Right Data Center Solutions: Key Factors to Consider

Understanding Different Types of MPO Breakout Cables

About US

Follow Us

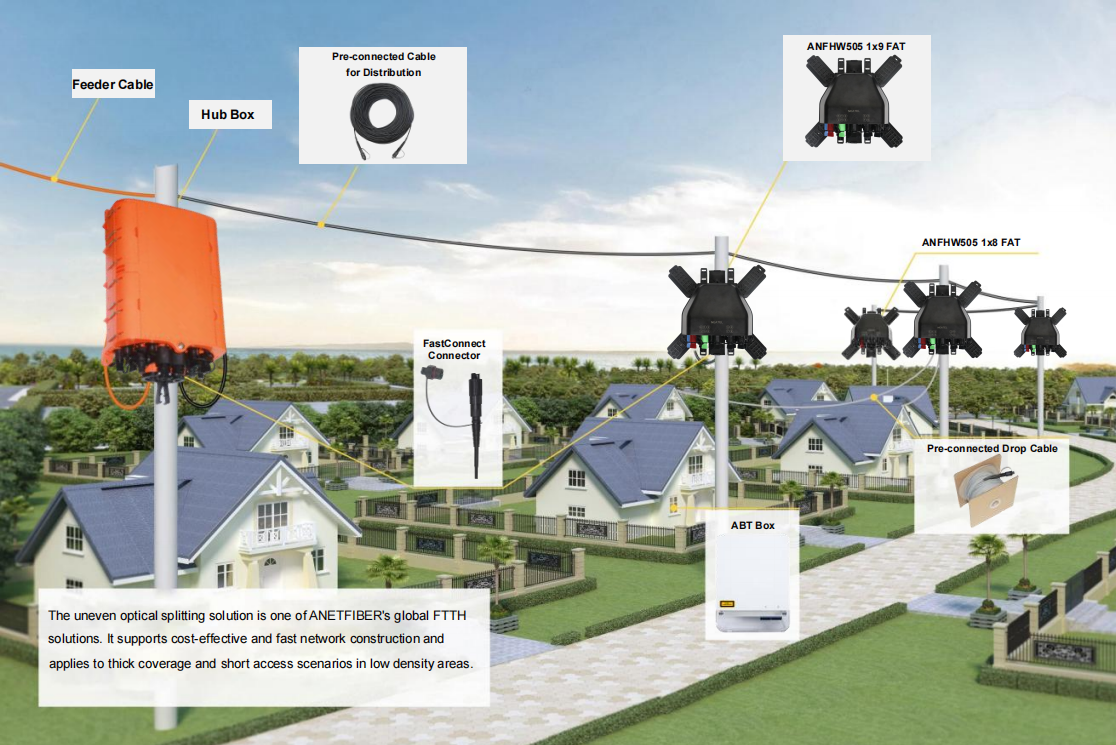

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586