How to Choose Reliable Fiber Splice Closures

Fiber splice closures play a crucial role in telecommunications and fiber connectivity. These small, rugged boxes protect sensitive areas of fiber optics from environmental factors. Reliable splice closures ensure minimal signal loss and enhanced dependability. Effective splicing fiber relies on precise fiber preparation and the correct use of specialized tools. Choosing a reliable fiber closure is essential for maintaining network integrity. A quality splice closure can significantly reduce issues related to fiber optics, making it a vital component in FTTx networks. Proper fiber closure selection is key to ensuring efficient fiberconnectivity and overall network performance.

Understanding Fiber Splice Closures

Definition and Purpose

What are Fiber Splice Closures?

Fiber splice closures are small, rugged boxes made from high-tension plastic. These closures protect sensitive fiber optic cabling areas from environmental factors. The construction includes a reliable moisture barrier and aging-resistant materials. This ensures durability against ultraviolet light and other natural elements. Fiber splice closures are essential for maintaining the integrity of fiber optic networks.

Why are they important in fiber optic networks?

Fiber splice closures play a crucial role in telecommunications. They ensure minimal signal loss and enhanced dependability. Properly sealed closures prevent moisture and dust from entering, which can degrade performance. Reliable closures help maintain efficient fiberconnectivity and overall network performance. They are vital components in FTTx networks, ensuring long-term reliability and reduced maintenance needs.

Types of Fiber Splice Closures

Dome Type

Dome-type fiber splice closures are designed for various applications, including underground installations. These closures require high-level seals and waterproof technology. The dome shape provides ample space for splicing and organizing cables. Made of excellent engineering plastics, these closures offer multiple inlet/outlet ports for different fiber optic core numbers. This type is ideal for environments where robust protection is necessary.

Inline Type

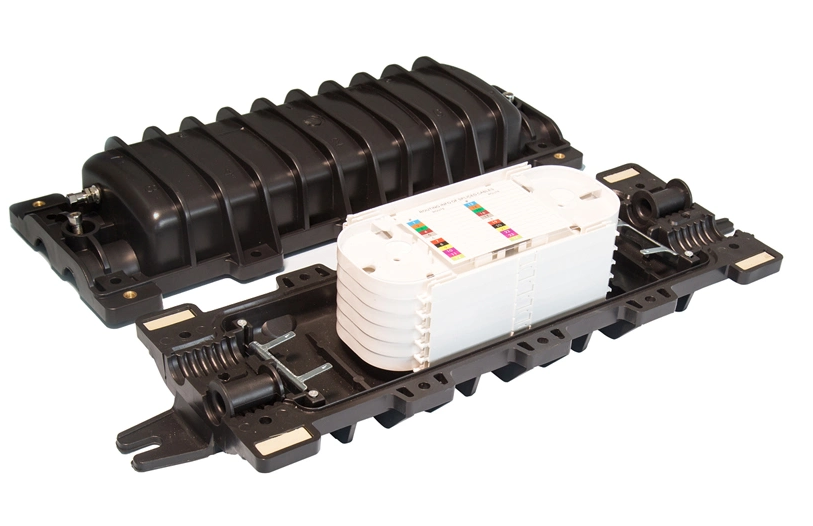

Inline fiber splice closures are suitable for major splice points in networks. These closures support a large number of splices with room for expansion. Designed to be waterproof and dustproof, inline closures are made of high tensile construction plastic. They provide good adaptability and compression resistance. Inline closures are often used in horizontal configurations, making them versatile for various network demands.

Aerial Type

Aerial fiber splice closures are optimized for installations above ground. These closures are typically mounted on poles or towers. Made from rugged plastics, aerial closures protect sensitive cabling from environmental elements. They offer ease of accessibility and multiple placement options. Aerial closures handle different splice types and strength members, ensuring reliable performance in elevated positions.

Underground Type

Underground fiber splice closures are designed for buried installations. These closures must withstand harsh conditions such as moisture and soil pressure. Made from high-tension plastic, underground closures feature reliable sealing mechanisms. They resist aging due to natural environmental factors. These closures provide leak-proof protection, ensuring long-term durability and network safety.

Key Factors to Consider

Environmental Conditions

Weather Resistance

Fiber splice closures must withstand various weather conditions. High-quality closures feature weather-resistant materials. These materials protect against rain, snow, and wind. Proper sealing mechanisms prevent water ingress. This ensures the longevity of the fiber optic network.

Temperature Tolerance

Temperature fluctuations can affect fiber splice closures. Reliable closures maintain performance in extreme temperatures. Materials used in these closures resist expansion and contraction. This prevents damage to the fiber optic cables inside. Consistent performance across temperature ranges is crucial.

Capacity and Size

Number of Splices

The number of splices a closure can handle is vital. Network demands determine the required splice capacity. Closures with higher capacities support more connections. This allows for network expansion without replacing the closure. Choosing the correct capacity ensures efficient network management.

Physical Dimensions

Physical dimensions of splice closures impact installation. Smaller closures fit in confined spaces. Larger closures provide more room for splicing and cable management. The installation environment dictates the appropriate size. Proper sizing ensures ease of installation and maintenance.

Material and Durability

Material Types

Different materials offer varying levels of protection. High-tension plastics are common in fiber splice closures. These materials provide strength and durability. Some closures use metal components for added robustness. The choice of material affects the closure's performance and lifespan.

Longevity and Maintenance

Durable materials ensure long-lasting splice closures. Regular maintenance extends the life of the closure. Easy-to-maintain closures reduce downtime. This enhances network reliability. Choosing durable and low-maintenance closures is essential for long-term network performance.

Ease of Installation and Maintenance

Installation Process

Fiber splice closures should offer a straightforward installation process. Technicians need clear instructions and user-friendly designs. High-quality closures often include pre-installed components. These components reduce setup time and minimize errors. Properly designed closures ensure secure connections and reliable performance. The installation process should accommodate various network configurations.

Maintenance Requirements

Regular maintenance is crucial for fiber splice closures. Durable materials reduce the frequency of required maintenance. Easy access to internal components simplifies upkeep. Closures with modular designs allow quick replacements of parts. This minimizes network downtime and enhances reliability. Maintenance-friendly closures ensure long-term network efficiency.

Cable Compatibility

Ensuring Proper Fit

Cable compatibility is essential for fiber splice closures. Closures must fit different cable types and sizes. Proper fit prevents damage to the fiber optic cables. Compatibility ensures secure connections and optimal performance. Technicians should verify the closure's specifications before installation.

Protection for Network

Fiber splice closures protect networks from environmental hazards. Reliable closures prevent moisture, dust, and other contaminants from entering. This protection maintains signal integrity and network performance. Closures with robust sealing mechanisms offer enhanced protection. Network safety depends on choosing the right closure.

Termination System

Efficient Connections

Efficient connections are vital for fiber optic networks. Fiber splice closures should support various termination systems. These systems ensure quick and reliable connections. Efficient connections reduce signal loss and improve network performance. Technicians should select closures that match the network's termination requirements.

Reliable Connections

Reliability is crucial for fiber optic connections. Fiber splice closures must provide consistent and dependable connections. High-quality materials and precise engineering contribute to reliability. Properly sealed closures prevent environmental factors from affecting connections. Reliable connections ensure long-term network stability and performance.

Types of Splices

Fusion Splicing

Fusion splicing involves joining two optical fibers by melting their ends together. This method creates a seamless connection with minimal signal loss. Technicians use specialized equipment to align and fuse the fibers accurately. Fusion splicing provides high-strength joints that withstand environmental stress. This technique is ideal for long-term reliability in fiber optic networks.

Mechanical Splicing

Mechanical splicing connects optical fibers using mechanical fixtures. These fixtures hold the fibers in precise alignment. The process does not require heat, making it quicker than fusion splicing. Mechanical splices offer flexibility for temporary or emergency repairs. However, these splices may introduce slightly higher signal loss compared to fusion splicing. This method suits scenarios where rapid deployment is necessary.

Bonding and Grounding Mechanisms

Electrical Protection

Fiber splice closures must include effective bonding and grounding mechanisms. Proper grounding protects the network from electrical surges and lightning strikes. Bonding ensures all metallic components within the closure are electrically connected. This reduces the risk of electrical faults. Reliable bonding and grounding mechanisms enhance the overall safety of the fiber optic network.

Network Safety

Network safety depends on robust bonding and grounding practices. These mechanisms prevent electrical interference from affecting the fiber optic cables. Properly grounded closures reduce the risk of damage during electrical storms. Ensuring network safety involves regular inspection and maintenance of bonding and grounding systems. This practice maintains the integrity and performance of the fiber optic network.

Hardware and Accessories

Ease of Installation

High-quality hardware and accessories simplify the installation process. Pre-installed components and user-friendly designs reduce setup time. Technicians benefit from clear instructions and intuitive layouts. Efficient hardware ensures secure connections and reliable performance. Choosing closures with easy-to-install features enhances overall network efficiency.

Maintenance

Maintenance-friendly hardware and accessories are crucial for long-term network performance. Modular designs allow quick replacement of parts without disrupting the entire system. Easy access to internal components simplifies routine inspections and repairs. Durable materials reduce the frequency of maintenance activities. Investing in maintenance-friendly closures minimizes network downtime and ensures consistent performance.

Cable Management Features

Organizing Cables

Effective cable management is crucial for maintaining a tidy and efficient fiber optic network. Fiber splice closures should include features that help organize cables neatly. Proper organization prevents tangling and makes future maintenance easier. Technicians can quickly identify and access specific cables when needed.

Closures with built-in trays or compartments offer structured spaces for cable arrangement. These compartments keep cables separated and reduce the risk of damage. Color-coded labels or markers can further enhance organization by providing visual cues for different cable types.

Protecting Cables

Protecting cables within splice closures ensures the longevity and reliability of the network. High-quality closures feature robust materials that shield cables from environmental hazards. These materials resist moisture, dust, and physical impacts, safeguarding the delicate fiber optics inside.

Sealing mechanisms play a vital role in cable protection. Reliable seals prevent contaminants from entering the closure. This maintains signal integrity and network performance. Closures with gaskets or O-rings provide an additional layer of protection against external elements.

Cable strain relief is another important aspect of protection. Strain relief features secure cables in place, preventing them from being pulled or bent excessively. This reduces the risk of damage and ensures stable connections. Properly designed closures incorporate strain relief to enhance overall network safety.

Additional Tips for Selection

Vendor Reputation

Researching Vendors

Researching vendors is crucial when selecting fiber splice closures. Reliable vendors provide high-quality products and excellent customer service. A thorough investigation of a vendor's history and market presence helps in making informed decisions. Look for vendors with a proven track record in the telecommunications industry. Established vendors often have better quality control measures in place.

Customer Reviews

Customer reviews offer valuable insights into a vendor's reliability. Positive reviews indicate customer satisfaction and product effectiveness. Negative reviews highlight potential issues and areas for improvement. Reading multiple reviews provides a balanced perspective. Verified purchase reviews carry more weight as they come from actual users. Consider both the quantity and quality of reviews before making a decision.

Cost vs. Quality

Budget Considerations

Budget considerations play a significant role in choosing fiber splice closures. High-quality closures often come with a higher price tag. However, investing in quality can lead to long-term savings. Cheaper options might require frequent replacements and maintenance. Allocating a sufficient budget ensures the purchase of durable and reliable closures. Weighing the initial cost against potential future expenses is essential.

Balancing Cost and Quality

Balancing cost and quality involves evaluating the trade-offs. High-quality closures offer better protection and longevity. Lower-cost options might compromise on materials and durability. Assessing the specific needs of the network helps in making this decision. Investing in quality reduces the risk of network failures and maintenance costs. A well-balanced choice ensures optimal performance and cost-efficiency.

Future-Proofing

Scalability

Scalability is a key factor in future-proofing fiber splice closures. Networks often expand over time, requiring additional splices and connections. Choosing closures with higher capacity supports future growth. Modular designs allow for easy upgrades without replacing the entire closure. Planning for scalability ensures the network can adapt to increasing demands.

Technological Advancements

Technological advancements impact the selection of fiber splice closures. New materials and designs offer improved performance and durability. Staying updated with the latest developments helps in making informed choices. Vendors that invest in research and development often provide cutting-edge solutions. Embracing technological advancements ensures the network remains efficient and up-to-date.

Choosing reliable fiber splice closures requires careful consideration of several factors. Key points include understanding different types, evaluating environmental conditions, and assessing capacity and size. Material durability and ease of installation also play critical roles. Proper cable management and effective bonding mechanisms ensure network safety.

Selecting the right closure enhances network performance and longevity. Consider vendor reputation and balance cost with quality. Future-proofing through scalability and technological advancements ensures long-term efficiency. For optimal results, follow these guidelines and consult trusted vendors for product recommendations.

See Also

MPO Cable Assemblies for Modern Data Centers

What Are Distribution Boxes and Their Functions in Fiber Optics

Selecting the Right IP68 Waterproof Connectors for Telecom Use

Choosing the Right Fiber Optic Distribution Box for Your Needs

About US

Follow Us

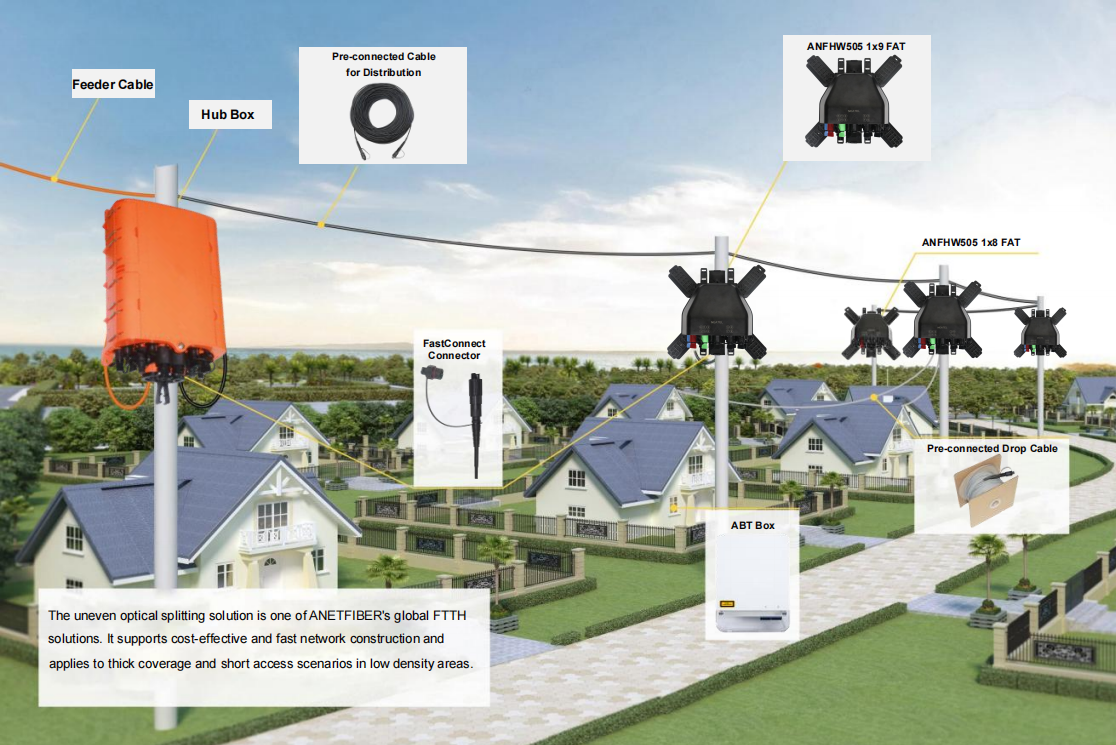

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586