3 Steps to Perfect Optical Signal with Fiberclosure

Fiber splice closures are essential for ensuring the reliability and performance of your network. They protect the delicate fibersplicing connections from environmental factors, which can affect the optical signal. You rely on these fiberclosure solutions to maintain good performance in various sectors, including telecommunications and data centers. Robust sealing methods in fiber closures safeguard cables, ensuring signal integrity and longevity. As data consumption surges, the demand for reliable transmission increases. Investing in quality fiber closures and terminal boxes, such as a fiberbox, becomes crucial. By understanding the importance of these components, you can enhance your network's efficiency and reliability.

Selecting the Appropriate Fiber Closure

Choosing the right fiber closure is crucial for maintaining a reliable network and ensuring good performance. You need to understand the different types of fiber closures available and consider various factors that influence your selection.

Understanding Different Types of Fiber Closures

Fiber closures come in several forms, each designed to meet specific needs in fiber optic networks. Here are the primary types you should know about:

Dome Closures

Dome closures are popular for their robust design and versatility. They provide excellent protection for fibersplicing in harsh environments. You can use them in aerial, underground, or direct-buried applications. Their dome-shaped structure allows for easy access and maintenance, making them a preferred choice for many network installations.

Inline Closures

Inline closures are ideal for long-distance transmission lines. They offer a streamlined design that aligns with the cable path, reducing the risk of signal loss. These closures are perfect for applications where space is limited, such as in ducts or conduits. By using inline closures, you ensure that your opticalsignal remains strong and uninterrupted.

Factors to Consider in Selection

When selecting a fiberclosure, you must evaluate several critical factors to ensure optimal performance and longevity.

Environmental Conditions

Consider the environmental conditions where the fiberclosure will be installed. Harsh weather, temperature fluctuations, and exposure to moisture can affect the integrity of your network. Choose closures that offer robust sealing and protection against these elements. This ensures that your fibersplicing remains secure and your network maintains good performance.

Network Requirements

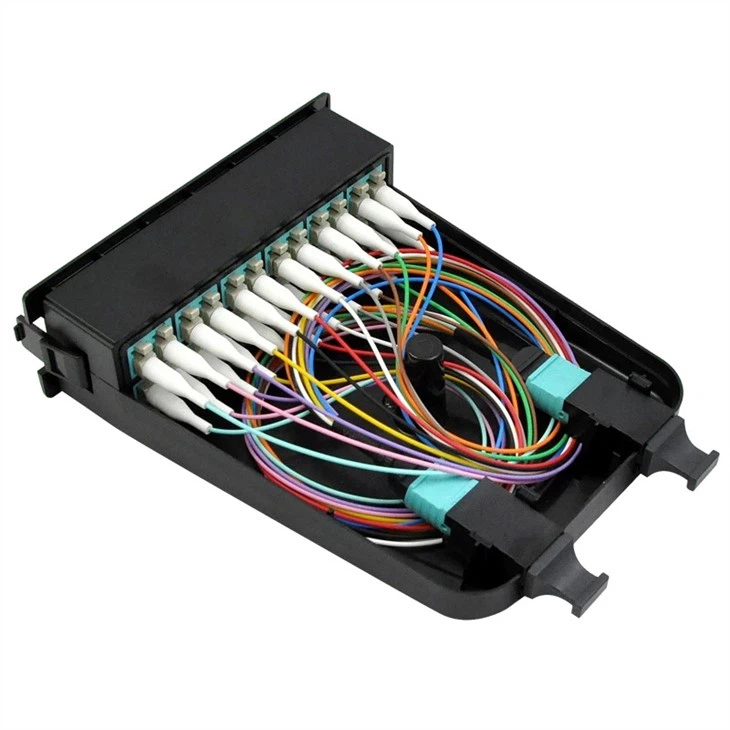

Your network's specific requirements also play a significant role in choosing the right closure. Assess the number of fibers you need to splice and the type of transmission you aim to achieve. Some closures, like those from Corning, offer optimized pairings with cables to enhance network safety and efficiency. Additionally, consider the need for a terminalbox or fiberbox to manage connections effectively.

By understanding these types and factors, you can select the most suitable fiberclosure for your network. This decision will help you maintain a reliable opticalsignal and support the increasing demand for high-speed connectivity.

Installation Process of Fiber Closure

Proper installation of a fiberclosure is crucial for maintaining a reliable network and ensuring good performance. This process involves several key steps that you must follow to achieve optimal results.

Preparing the Fiber Cables

Before you begin the installation, you need to prepare the fiber cables meticulously. This preparation ensures that the fibersplicing process proceeds smoothly and efficiently.

Stripping and Cleaning

Start by stripping the protective coating from the fiber cables. Use a precision stripper to avoid damaging the delicate fibers. Once stripped, clean the fibers thoroughly to remove any dust or debris. This step is vital as contaminants can affect the quality of the opticalsignal.

Organizing the Fibers

After cleaning, organize the fibers systematically. Group them according to their intended connections. This organization simplifies the splicing process and reduces the risk of errors. Proper organization also facilitates easier maintenance and troubleshooting in the future.

Splicing and Securing the Fibers

With the fibers prepared, you can proceed to splice and secure them. This step is critical for ensuring a stable and efficient transmission of data.

Fusion Splicing

Fusion splicing is the preferred method for creating a permanent connection between fibers. It involves aligning the fibers precisely and using an electric arc to fuse them together. This method provides a low-loss connection, which is essential for maintaining a strong opticalsignal over long distances.

Mechanical Splicing

Alternatively, you can use mechanical splicing. This method involves aligning the fibers within a mechanical fixture. While it offers flexibility and re-enterability, it may not provide the same level of performance as fusion splicing. Choose the method that best suits your network's requirements and conditions.

Sealing and Testing the Closure

Once the fibers are spliced, you must seal and test the fiberclosure to ensure its integrity and performance.

Ensuring Proper Sealing

Select the appropriate sealing method based on the installation conditions and environmental challenges. Heat-shrinkable options offer a reliable and tight seal, but they lack the flexibility of mechanical closures. Ensure that the closure is sealed properly to protect the fibers from moisture and other environmental factors.

Conducting Signal Tests

Finally, conduct signal tests to verify the quality of the transmission. Use specialized equipment to measure the opticalsignal strength and detect any potential issues. Regular testing helps maintain good performance and ensures that your network operates efficiently.

By following these steps, you can install a fiberclosure effectively, ensuring a robust and reliable network. This process not only enhances the performance of your fibersplicing but also supports the increasing demand for high-speed connectivity.

Maintenance and Troubleshooting Tips

Maintaining your fiberclosure is essential for ensuring good performance and longevity of your network. Regular inspections and proactive troubleshooting can prevent issues that might disrupt the opticalsignal. Here are some key practices to keep your fibersplicing in top condition.

Regular Inspection and Cleaning

Routine checks and cleaning are vital for maintaining the integrity of your fiberclosure. These steps help you identify potential problems before they escalate.

Identifying Wear and Tear

Inspect your fiberclosure regularly for signs of wear and tear. Look for cracks, moisture ingress, or any physical damage that might compromise the closure's effectiveness. Pay attention to the sealing methods used, as improper sealing can lead to environmental damage. Identifying these issues early allows you to address them promptly, ensuring the continued protection of your fibersplicing.

Cleaning Procedures

Cleaning your fiberclosure involves removing dust, dirt, and other contaminants that can affect the opticalsignal. Use appropriate cleaning tools and solutions to gently clean the fibers and the closure itself. Regular cleaning not only maintains good performance but also extends the lifespan of your network components.

Troubleshooting Common Issues

Even with regular maintenance, issues can arise. Knowing how to troubleshoot common problems ensures that you can quickly restore your network's functionality.

Signal Loss

Signal loss is a common issue that can affect transmission quality. To address this, check the alignment of your fibersplicing. Misalignment can cause significant signal degradation. Re-splice the fibers if necessary, using high-quality tools to ensure a precise connection. Additionally, inspect the terminalbox and fiberbox for any loose connections that might contribute to signal loss.

Physical Damage

Physical damage to the fiberclosure or the fibers themselves can disrupt network performance. Examine the closure for any visible damage and replace any worn or broken components. If the fibers are damaged, re-splicing may be required. Ensure that you use durable materials and robust sealing methods to prevent future damage.

By following these maintenance and troubleshooting tips, you can ensure that your fiberclosure continues to provide reliable protection and support for your network. Regular care and prompt attention to issues will help maintain a strong opticalsignal and meet the growing demand for high-speed connectivity.

In summary, achieving a perfect opticalsignal involves three crucial steps: selecting the right fiberclosure, ensuring proper installation, and maintaining regular upkeep. By managing your fibersplicing effectively, you enhance network reliability and ensure goodperformance. Proper fiberclosure management protects your network from environmental factors, ensuring seamless transmission. Applying these steps will optimize your network's performance, meeting the growing demand for high-speed connectivity. Equip your network with a reliable terminalbox or fiberbox to manage connections efficiently. Embrace these practices to maintain a robust and efficient network.

See Also

Top 3 FTTH Fibertech Tips for 4G Networks

MPO Connectors: Driving Innovation in Data Center Design

Enhancing Fiber Deployments with Invisible Cable Technology

About US

Follow Us

AnetFiber company's main products are indoor and outdoor optical fiber cables, outdoor waterproof pre-connected fiber-to-the-home products, PLC optical fiber splitters, optical fiber jumpers and pigtails, MTP®/MPO high-density big data product solutions, optical fiber field quick connectors and research and development molding, injection molding and production of optical fiber distribution boxes, optical fiber chassis cabinets, the market has expanded to the world, Europe, America, Asia, the Middle East and Latin America.

Address

Shenzhen City, Baoan District, Yanluo Street, Tangxiayong Community, Yangyong Industrial Road, Tonggangda New Energy Vehicle Park 406

Contacts

+86 199 2655 3586